The application cases of graphite milling cutters

Release time:

2023-07-13

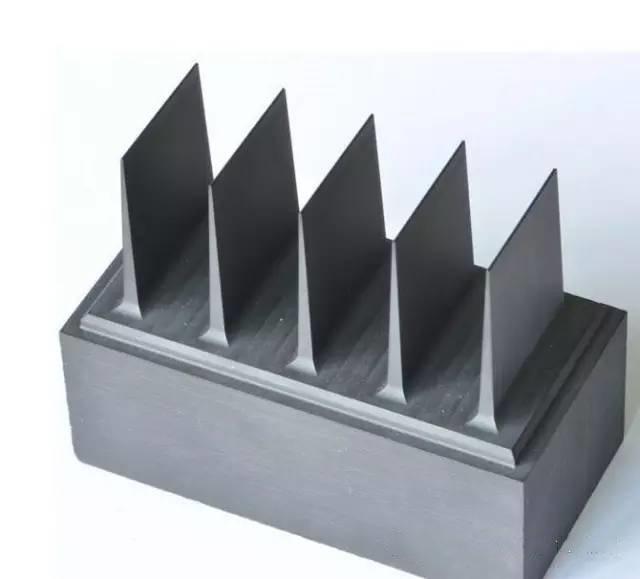

Due to the advantages of fast discharge speed, light weight, good thermal stability, and high possibility of forming complex shapes, more and more mold customers are using graphite as the preferred electrode material. At the same time, due to the characteristics of graphite material and the different cutting principles from metals, the processing of graphite not only puts higher requirements on cutting tools, but also has significant differences in processing strategies from typical copper electrodes. How to efficiently process graphite electrodes poses great challenges for customers themselves. Nanjing Jianchuanshi has a wealth of processing experience in the field of graphite processing. Jianshi is willing to help customers improve the processing efficiency of its graphite electrodes, and then leverage the advantages of graphite electrodes in molds and products.

Due to the advantages of fast discharge speed, light weight, good thermal stability, and high possibility of forming complex shapes, more and more mold customers are using graphite as the preferred electrode material. At the same time, due to the characteristics of graphite material and the different cutting principles from metals, the processing of graphite not only puts higher requirements on cutting tools, but also has significant differences in processing strategies from typical copper electrodes. How to efficiently process graphite electrodes poses great challenges for customers themselves. Nanjing Jianchuanshi has a wealth of processing experience in the field of graphite processing. Jianshi is willing to help customers improve the processing efficiency of its graphite electrodes, and then leverage the advantages of graphite electrodes in molds and products.

Graphite material

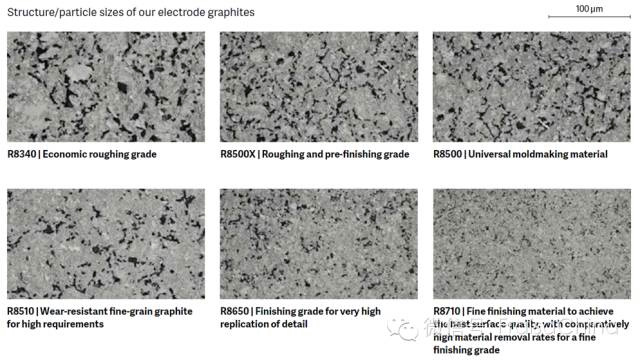

Graphite is a common mineral material, and pencils contain graphite. The chemical pure carbon content of powdered graphite is 99.97%, with high hardness (similar to tungsten steel), non-toxic powder, and even very small dust will not self ignite or explode. In addition, it has high conductivity and thermal stability, a specific gravity four times smaller than copper (light), acid resistance, and no magnetism, which are also the reasons why it can be used as an electrode. There are 7 graphite producers worldwide. Each manufacturer has 6 specifications, totaling approximately 50 types. The different particle sizes of graphite determine the characteristics of different graphite grades.

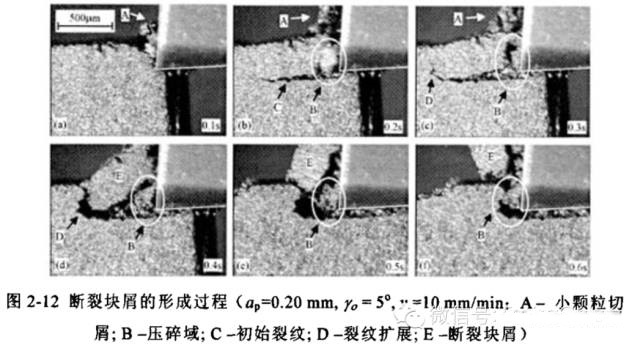

Principles of Graphite Cutting

Unlike the principle of plastic deformation caused by metal cutting, the principle of graphite processing is to use tool impact to cause cracks and propagation in graphite materials, ultimately leading to detachment. The cutting force during graphite processing is about 10% of that used to cut tough metals such as aluminum and copper; And due to its good thermal conductivity, cutting temperature is not a problem for graphite processing.

Processing strategy

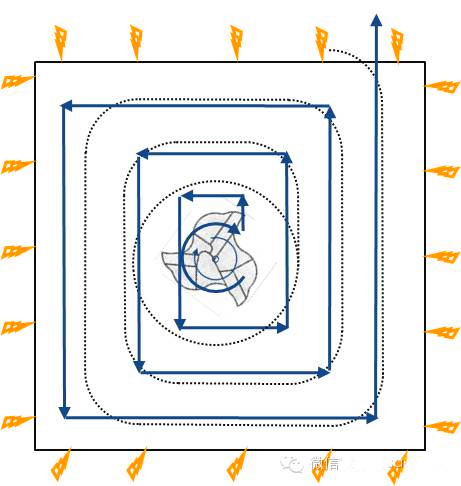

The machining strategy of graphite milling is crucial. Even with the same diamond coated tool, the tool life can differ by several times using different programming strategies under the same cutting parameters. At the same time, the correct processing strategy can reasonably avoid problems such as graphite electrode bouncing and improve the surface quality of the electrode. The milling of graphite electrodes is closely related to electrical discharge machining, which requires engineers to not only have milling knowledge, but also have a certain understanding of electrical discharge machining.

Graphite milling cutter (diamond coated tool)

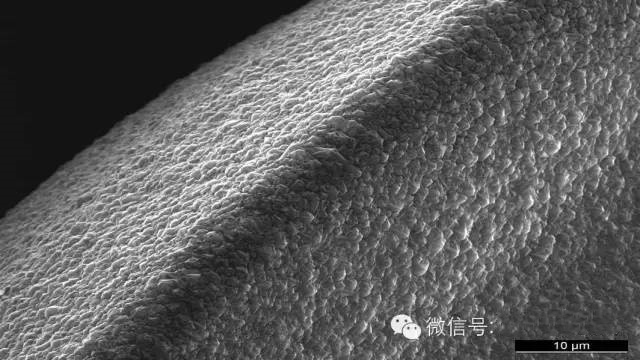

As is well known, due to the high hardness of graphite materials, diamond coated milling cutters are the best choice for processing graphite. The coating itself also poses high requirements for the hard alloy substrate. Diamond coating is a CVD chemical coating, and it is also the most difficult type of coating. The crystal structure composition and proportion of carbon elements have a significant impact on the performance.

Application Cases/Demo Parts

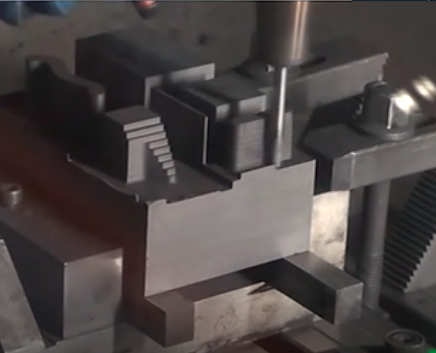

1. Face milling processing

Processing parameters:

VC=565m/min

fz=0.08

n=30000rev/min

vf=4800

ap=0.35mm

ae=3mm

2. Slot milling and imitation processing

VC=565m/min

fz=0.055

n=30000rev/min

vf=3300

ap=2.7mm

ae=6mm

Arrow-Stone Industry & Trade is willing to help our customers provide or improve processing solutions for graphite electrodes in molds. If you have any questions, please contact us.

Related Cases