High-speed rail bearing cage processing case

Release time:

2022-04-18

1. finished products meet customer product quality requirements.

The 2. beat basically meets the customer's specified time.

Single-piece processing costs are reduced by about 135 percent 3. comparing outsourced processing costs.

Product Name: High-speed rail bearing cage

Material: 40GrNiMoA Hardness: 32-35HRC

Machine Tools: FEELER Vertical Machining Center VM-1000AT

Client: a high-speed rail bearing co., LTD

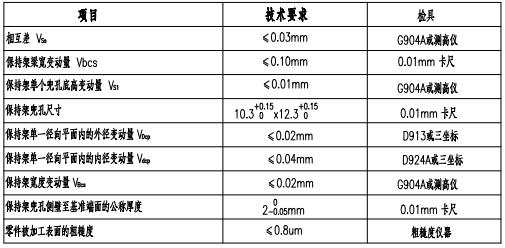

Processing requirements:

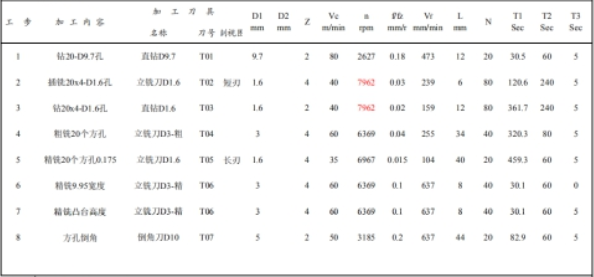

Processing beat:

Tool parameter details:

T1: Jinlu D938 Series Tungsten Steel Drill φ9.7 Drilling Speed: 3000r/min; Feed: 350 mm/min

T2: Golden Heron UP210 Series Tungsten Steel Milling Cutter Φ 1.6 Insertion Milling Speed: 6000r/min; Feed: 30 mm/min

T3: Jinlu D938 Series Tungsten Steel Drill φ1.6 Drilling Speed: 6000r/min; Feed: 60 mm/min

T4: Jinlu UPR210 Series Tungsten Steel Rough Milling Cutter φ6 Rough Milling Speed: 6000r/min; Feed: 700 mm/min

T5: Golden Heron UP210 Series Tungsten Steel Milling Cutter φ3 Precision Milling Speed: 7000r/min; Feed: 150 mm/min

T6: South Korea YESTOOLS Tungsten Steel Milling Cutter φ1.5 Finishing Milling Speed: 7000r/min; Feed: 150 mm/min

T7: South Korea YESTOOLS forward and reverse chamfering cutter chamfering speed: 6000r/min; Feed: 700 mm/min

Full program design, tool equipped.

Summary:

1. finished products meet customer product quality requirements.

The 2. beat basically meets the customer's specified time.

Single-piece processing costs are reduced by about 135 percent 3. comparing outsourced processing costs.

Related Cases

New Da'an

Follow us

Nanjing Arrow-Stone Industry Co. ,Ltd

Telephone: 86 025 84958290

Address: No. 105, Building 8, District 8, Lingxin Market, Jiangning District, Nanjing