This test knife is an improved test knife.

Customer Purpose:

1. Improve the problems of insufficient finish and burrs of existing products.

2, improve production efficiency.

3, cost savings.

Test results;

1, product finish perfect marking, chamfer burr problem solved.

2, compared with the existing efficiency of about 25%.

3, production costs are basically flat.

Cylinder hole machining

Client: an automobile company limited by shares

Workpiece: PUMA2.2/2.4 cylinder

Material: GG25

Processing equipment: Starragheckert HEC500

Processing procedure: OP130B

Processing content:

1. Semi-fine boring cylinder hole

2. Cylinder hole orifice chamfer

3. Fine boring cylinder hole

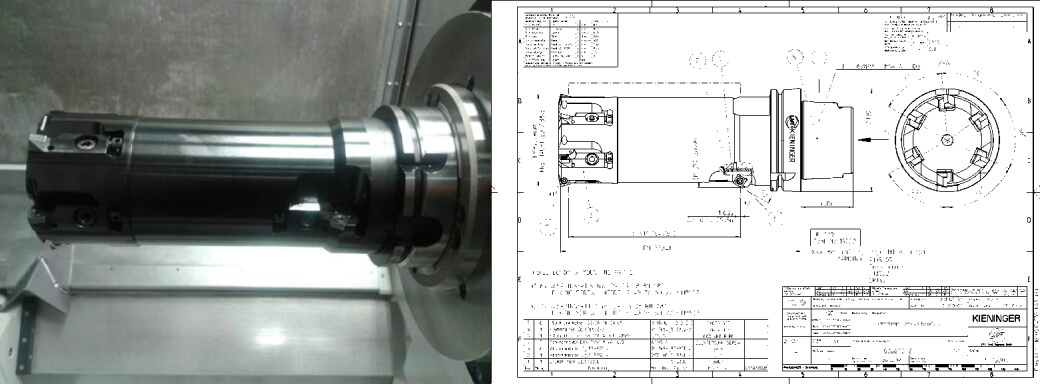

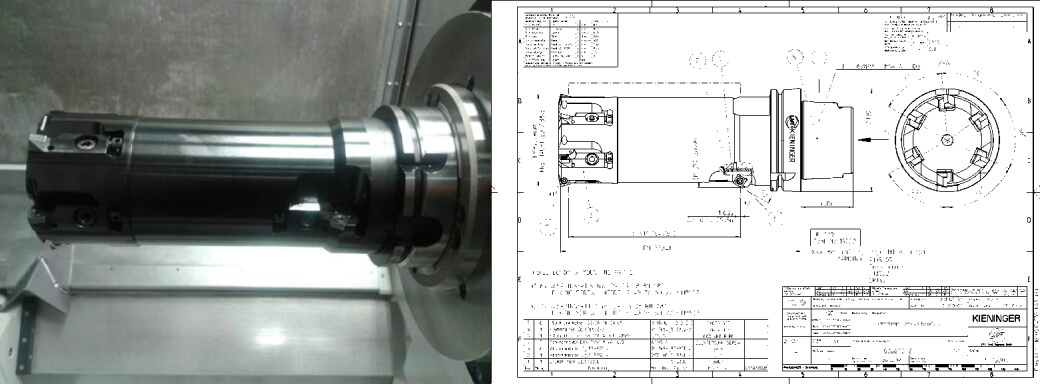

Cylinder bore semi-finishing

Tool: semi-fine boring cylinder hole step boring tool

Cutting parameters:

Φ89.4

Z = 6 (SCGW 09T308 BN081)

VC=850m/min

n=3000 U/min

Fz=0.16

F=2880 mm/min

Cylinder bore finishing

Tool: fine boring cylinder hole fine boring tool (using internal cooling open mode)

Cutting parameters:

Φ 89.86±0.02

Z = 3 (SCGW 09T308 E BN081)

VC=850m/min

n=3000 U/min

Fz=0.1

F=900 mm/min

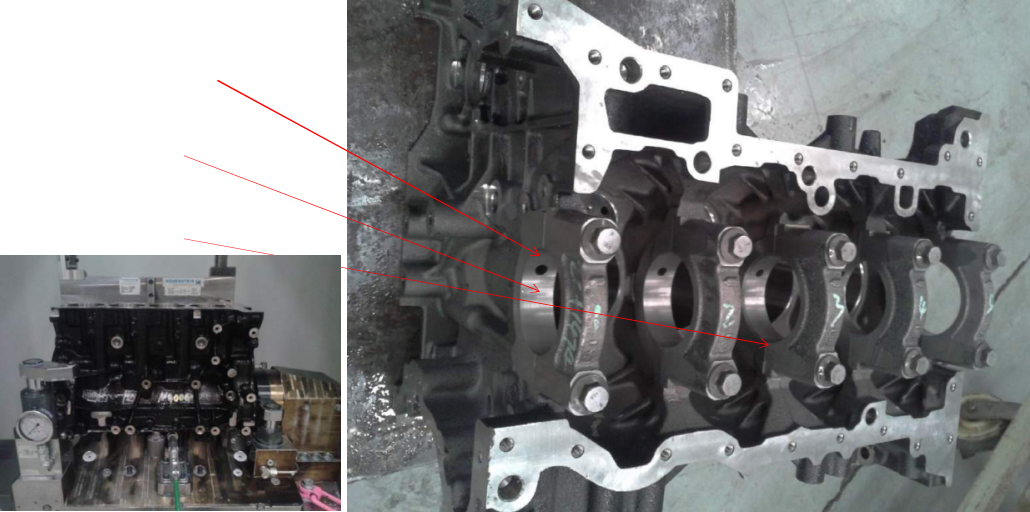

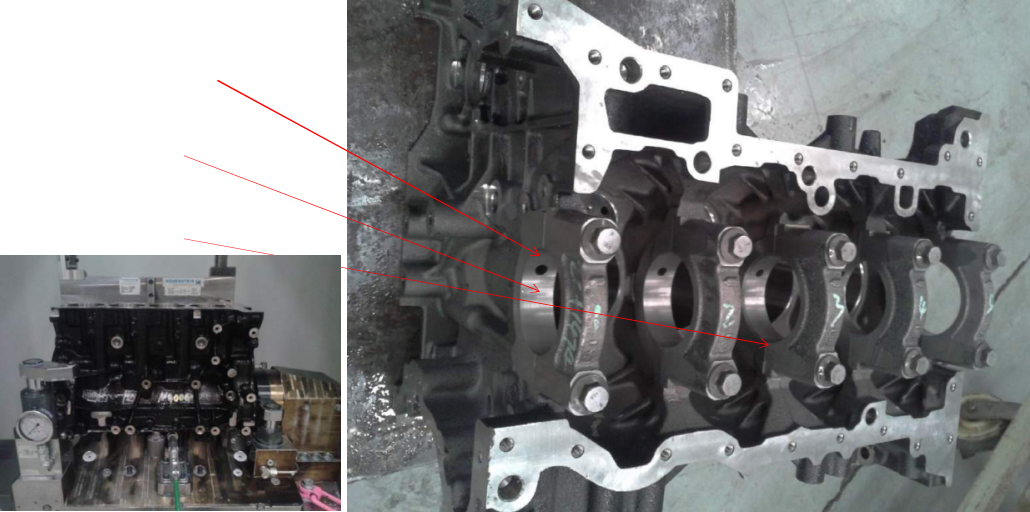

Crankshaft hole machining

Processing: OP140B

Processing content:

1. Semi-finish boring crankshaft hole

2. Fine boring crankshaft hole

3. Precision turning thrust surface

Semi-finishing crankshaft hole

Cutter: Φ69-0.1/ Φ74-0.1/45 ° chamfer

compound line boring tool for semi-fine boring crankshaft hole

The semi-fine boring crankshaft hole and the chamfering at both ends of the crankshaft hole are finished at one time.

Z = 1(SCGW 09T304 LC610T)

Cutting parameters:

VC=100m/min

n=460 U/min

Fz=0.15

F= 69mm/min

Thrust surface finishing of crankshaft hole

Φ104.2 Precision turning thrust surface contact type moving tool

The semi-precision and precision turning thrust surface is processed at one time.

Z = 1(CPGW 09T304 LC610T)

Cutting parameters:

VC=120m/min

n=280 U/min

Fz=0.2 F= 56mm/min

Crankshaft hole finishing

Φ 69.46±0.015 fine boring crankshaft hole line boring tool

Z = 1(SCGW 09T304 LC610T)

Compared with the traditional fine boring unit, the KIEINIGER semi-circular fine boring cutter holder can bring better cross-sectional strength to the boring bar, thus enhancing the rigidity of the boring bar.

Cutting parameters:

VC=125m/min

n=570 U/min

Fz=0.15

F=86 mm/min