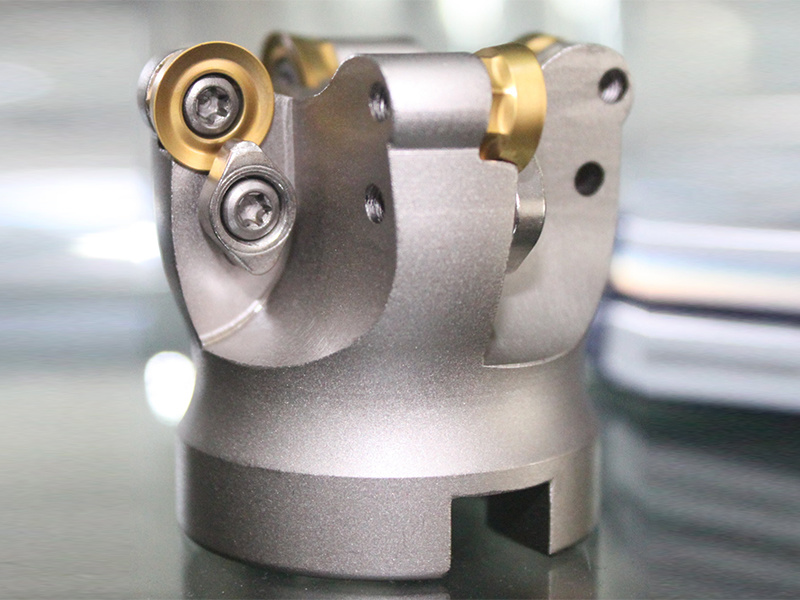

Milling insert

Our company specializes in cutting tools for more than ten years! Many agent brands: Sandvik; Kennametal; YG-1; WALTER; GESAC; YESTOOL; TT ; Zhengheyuan (SYIC) and other advantageous channels: SCHUNK, HAIMER, Seco, ISCAR, DOMA , Nikken and many European and American products; In addition: our company undertakes drill bits, drill tips, milling cutter mold modifications, and coatings, non-standard customization and program design, sales services such as fixtures, jigs, and measuring tools. Excellent quality! Price guaranteed! Delivery time guaranteed! Welcome to come for consultation.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Milling refers to the use of rotating multi-edged tools to cut workpieces, and is a highly efficient processing method. During work, the tool rotates (makes the main motion) and the workpiece moves (makes the feed motion). The workpiece can also be fixed, but at this time the rotating tool must also move (complete the main motion and feed motion at the same time). Milling machine tools include horizontal milling machines or vertical milling machines , as well as large gantry milling machines. These machine tools can be ordinary machine tools or CNC machine tools . Cutting using a rotating milling cutter as a tool . Milling is generally performed ona milling machine or boring machine , and is suitable for processing planes, grooves, various forming surfaces (such as splines, gears and threads) and special shaped surfaces of molds.

main application

(1)Planar parts

The horizontal characteristics of planar parts are that the processed surface can be parallel to the plane, perpendicular to the horizontal plane, or at a fixed angle to the horizontal plane; most parts processed on CNC milling machines are planar parts, and planar parts are The The simplest type of parts in CNC milling processing generally only requires two-axis linkage or three-axis linkage of a three-axis CNC milling machine. During the machining process, the machining surface is in surface contact with the tool, and end mills or bull -nose cutters can be used for roughing and finishing.

(2) Curved surface parts

The characteristic of curved parts is that the processing surface is a spatial curved surface. During the processing process, the processing surface and the milling cutter are always in point contact. Surface finishing is mostly performed using ball end milling cutters .

Our company specializes in cutting tools for more than ten years!

Many agent brands:

Sandvik; Kennametal; YG-1; WALTER; GESAC; YESTOOL; TT ; Zhengheyuan (SYIC) and other

advantageous channels: SCHUNK, HAIMER, Seco, ISCAR, DOMA , Nikken and many European and American products;

In addition: our company undertakes drill bits, drill tips, milling cutter mold modifications, and coatings, non-standard customization and program design, sales services such as fixtures, jigs, and measuring tools.

Excellent quality! Price guaranteed! Delivery time guaranteed! Welcome to come for consultation.

Related Products

Related Cases

Welcome your message consultation