South Korea a trace of YESTOOL

After more than 30 years of painstaking research and development, South Korea YESTOOL Company has covered major engine production plants and users with high requirements for drilling and processing around the world, overcoming numerous difficulties in the drilling field for them. to achieve high efficiency, high difficulty, low-cost processing requirements. Has developed a variety of replaceable blade, combination drill and other technologies, and has more than 20 core patents and more exclusive proprietary technology. Products have been sold to more than 60 countries and regions in the world. At present, world-renowned engine manufacturers such as Mercedes-Benz, BMW, Chrysler, MAN, Ford, GM, Honda, Hyundai, etc.; famous manufacturers such as Mitsubishi Elevator and Japan Dadong Seiki Co., Ltd. are widely using YESTOOL products. 1. The YESTOOL machine clamp type internal cooling drill, combined with the traditional twist drill and common indexable bit characteristics, that is, a good self-centering effect, but also convenient and quick replacement of the failure of the drill, thereby reducing the auxiliary time. The cutting part of the machine-clamped internal cold drill bit is made of whole hard alloy by full grinding. Its shape is basically the same as that of the traditional twist drill. The drill rod is centered by the center pin and fixed by the inclined wedge surface screw. It can replace the cutting part of the head conveniently and quickly like other indexable drill bits. The same specification of the drill pipe can be installed with five different diameters of the head so that the product can be more flexible to use in various occasions. The product series can process the aperture range of ф 8 ~ ф 50.4 or inch ф 0.315 "~ ф 2", each interval is 0.1mm. The drill pipe is divided into 3 × D, 5 × D and 7 × D series according to the hole depth. There are two categories of cylindrical straight handle and Morse taper handle. The maximum specification of Morse handle is ф 25.4/MT3. 2. Welding-edge drill bit is one of the YESTOOL products that are more concerned by Chinese users. He expanded the size range of large-diameter solid carbide drill bits, which can process ф 13.5 ~ ф 41.5 in diameter, with hole depths of 3 ×D and 5 ×D, and have internal cold water passage holes. The head is made of ultrafine cemented carbide material with TiN or TiAlN coating on the surface. The shaft is made of high-quality tool steel after heat treatment. The handle is a cylinder with chamfered edges, which can be applied to various clamping methods. 3. Integral carbide drill bits are YESTOOL standard regular products, with diameters from ф 3 to ф 20, hole depths of 3 ×D, 5 ×D and 8D, divided into two series with or without cooling water holes. Surface TIN or TIALN coatings are standard stock. According to the special requirements of the actual use of customers, the YESTOOL can choose different blanks, different sharpening treatments and different surface coatings for different processing object materials. It can also provide customers with special sizes such as step drills or specified manufacturing tolerances. All series of solid carbide drill bits are also available with inch bore. 4. The YESTOOL machine clamp milling cutter is specially suitable for mold processing industry and complex surface processing. With the same cutter bar, there can be five different shapes of cutter heads for replacement: ball head, semicircular ball head, rounded end milling cutter head, 60 vertex angle pointed milling cutter, 90 vertex angle pointed milling cutter, etc. All cutter heads are ground by integral hard alloy in the numerical control grinding center. High-performance, high-quality products can complete the coarse and fine requirements of the molding process. 5.YESTOOL solid carbide milling cutter has three categories: ball head, wave blade and cylinder. Cylindrical solid carbide milling cutter has two categories: 2 blades, 4 blades, 30 ° helix angle, 6 blades and 8 blades, 40 ° helix angle, which can meet the needs of different customers and different uses. If you have special needs, the same can be specially made for you.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

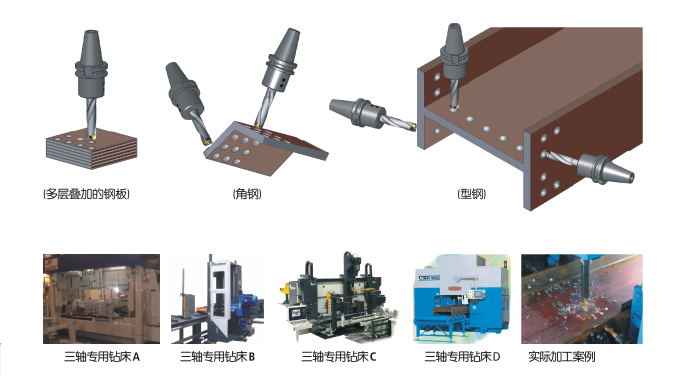

After more than 30 years of painstaking research and development, South Korea YESTOOL Company has covered major engine production plants and users with high requirements for drilling and processing around the world, overcoming numerous difficulties in the drilling field for them. to achieve high efficiency, high difficulty, low-cost processing requirements. Successively developed a variety of alternativeBladeWe have more than 20 core patents and more exclusive know-how. Products have been sold to more than 60 countries and regions in the world. At present, world-renowned engine manufacturers such as Mercedes-Benz, BMW, Chrysler, MAN, Ford, GM, Honda, Hyundai, etc.; famous manufacturers such as Mitsubishi Elevator and Japan Dadong Seiki Co., Ltd. are widely using YESTOOL products.

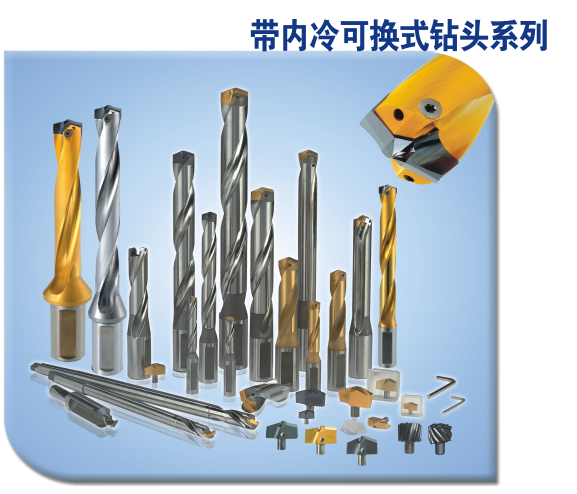

1. The YESTOOL machine clamp type internal cooling drill, combined with the traditional twist drill and common indexable bit characteristics, that is, a good self-centering effect, but also convenient and quick replacement of the failure of the drill, thereby reducing the auxiliary time. The cutting part of the machine-clamped internal cold drill bit is made of whole hard alloy by full grinding. Its shape is basically the same as that of the traditional twist drill. The drill rod is centered by the center pin and fixed by the inclined wedge surface screw. It can replace the cutting part of the head conveniently and quickly like other indexable drill bits. The same specification of the drill pipe can be installed with five different diameters of the head so that the product can be more flexible to use in various occasions. The product series can process the aperture range of ф 8 ~ ф 50.4 or inch ф 0.315 "~ ф 2", each interval is 0.1mm. The drill pipe is divided into 3 × D, 5 × D and 7 × D series according to the hole depth. There are two categories of cylindrical straight handle and Morse taper handle. The maximum specification of Morse handle is ф 25.4/MT3.

2. Welding-edge drill bit is one of the YESTOOL products that are more concerned by Chinese users. He expanded the size range of large-diameter solid carbide drill bits, which can process ф 13.5 ~ ф 41.5 in diameter, with hole depths of 3 ×D and 5 ×D, and have internal cold water passage holes. The head is made of ultrafine-grained cemented carbide material, with TiN or TiAlN coating on the surface, and the shaft is of high qualityToolsThe steel is made after heat treatment, and the shank is a cylinder with a chamfered edge, which can be used in various clamping methods.

3. Integral carbide drill bits are YESTOOL standard regular products, with diameters from ф 3 to ф 20, hole depths of 3 ×D, 5 ×D and 8D, divided into two series with or without cooling water holes. Surface TIN or TIALN coatings are standard stock. According to the special requirements of the actual use of customers, the YESTOOL can choose different blanks, different sharpening treatments and different surface coatings for different processing object materials. It can also provide customers with special sizes such as step drills or specified manufacturing tolerances. All series of solid carbide drill bits are also available with inch bore.

4. YESTOOL machine clamp typemilling cutter, specially suitable for mold processing industry and complex surface processing, the sameCutter bar, there can be five different shapes of cutter heads available for replacement: ball head, semicircular ball head, rounded end milling cutter head, 60 apex angle pointed milling cutter, 90 apex angle pointed milling cutter, etc. All cutter heads are ground with integral hard alloy in the CNC grinding center. High-performance, high-quality products can complete the coarse and fine requirements of the molding process.

5. YESTOOL solid carbide milling cutter has three categories: ball head, wave blade and cylinder. Cylindrical solid carbide milling cutter has two categories: 2 blades, 4 blades, 30 ° helix angle, 6 blades and 8 blades, 40 ° helix angle, which can meet the needs of different customers and different uses. If you have special needs, the same can be specially made for you.

Related Products

Related Cases

Welcome your message consultation