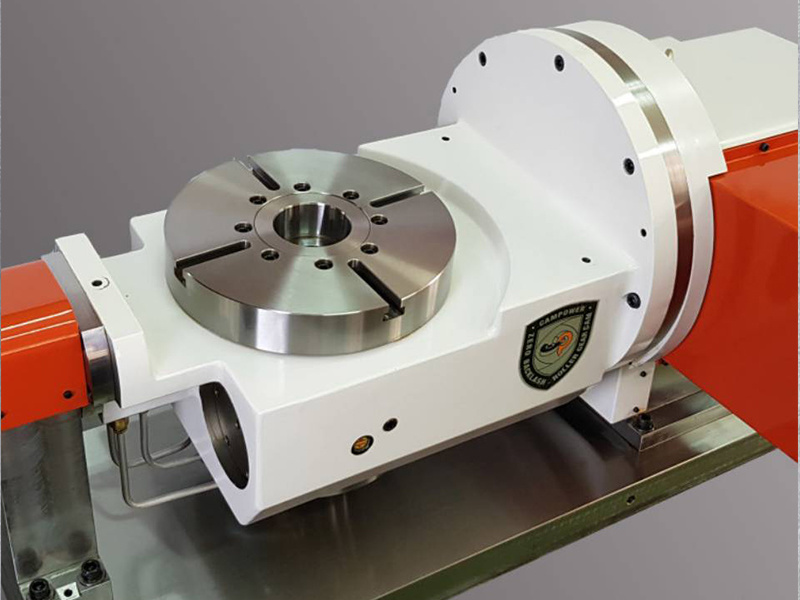

Side milling head

Side milling head, also known as angle head, is a machine tool accessory. After the milling head is installed on the machine tool, the tool rotation center line can process the workpiece at an angle with the spindle rotation center line. Originated in Europe, it is now widely used in various fields of mechanical processing such as aviation, automobiles, and molds. The use of milling heads can increase the processing range and adaptability of the machine tool without changing the structure, enabling some processing that is difficult to complete with traditional methods, reducing repeated clamping of workpieces, and improving processing accuracy and efficiency.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Side milling head, also known as angle head, is a machine tool accessory. After the milling head is installed on the machine tool, the tool rotation center line can process the workpiece at an angle with the spindle rotation center line. Originated in Europe, it is now widely used in various fields of mechanical processing such as aviation, automobiles, and molds. The use of milling heads can increase the processing range and adaptability of the machine tool without changing the structure, enabling some processing that is difficult to complete with traditional methods, reducing repeated clamping of workpieces, and improving processing accuracy and efficiency.

Mainly used in machining centers and gantry milling machines, the light ones can be installed in the tool magazine and can be freely converted between the tool magazine and the machine tool spindle; the medium and heavy ones have greater rigidity and torque and can be suitable for most processing needs.

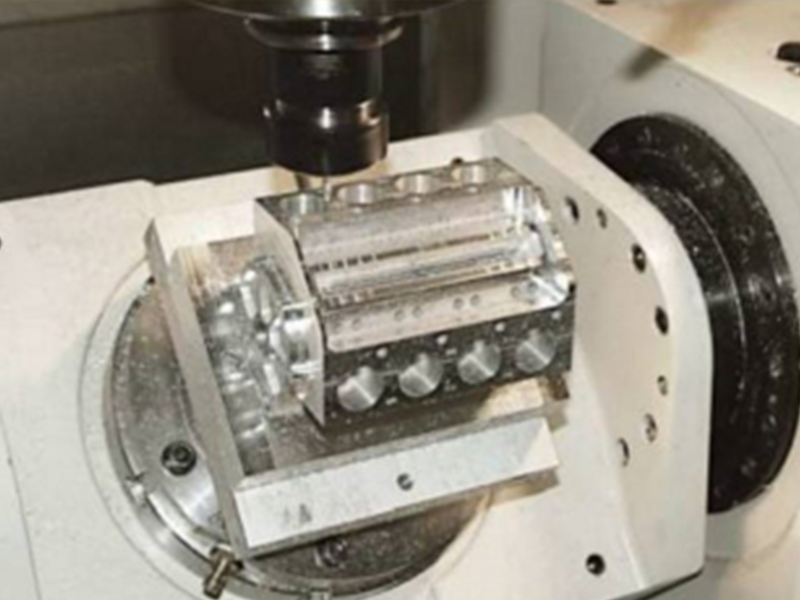

Because the milling head expands the performance of the machine tool, it is equivalent to adding an . It is even more practical than the fourth axis when some large workpieces are difficult to turn over or high precision is required.

Practical application

1. When it is difficult to fix large workpieces, it is used in simple processing;

2. Precision workpieces are fixed at one time and multiple surfaces need to be processed;

3. When processing at any angle relative to the datum plane;

4. The processing is maintained at a special angle for copy milling pins, such as ball head end milling;

5. When there is a hole in the hole, the milling head or other tools cannot penetrate into the hole to process the small hole;

6. Inclined holes, inclined grooves, etc. that cannot be processed by the machining center, such as internal holes in engines and cases, etc.

Nanjing Jianchuanshi Industry and Trade Co., Ltd. has specialized in cutting tools for more than ten years!

Many agent brands:

Sandvik; Kennametal; YG-1; WALTER; GESAC; YESTOOL; TT ; Zhengheyuan (SYIC) and other

advantageous channels: SCHUNK, HAIMER, Seco, ISCAR, DOMA, Nikken and many European and American products;

In addition: our company undertakes drill bits, drill tips, milling cutter mold modifications, and coatings, non-standard customization and program design, sales services such as fixtures, jigs, and measuring tools.

Excellent quality! Price guaranteed! Delivery time guaranteed! Welcome to come for consultation.

Related Products

Related Cases

Welcome your message consultation