Four-axis and five-axis machining

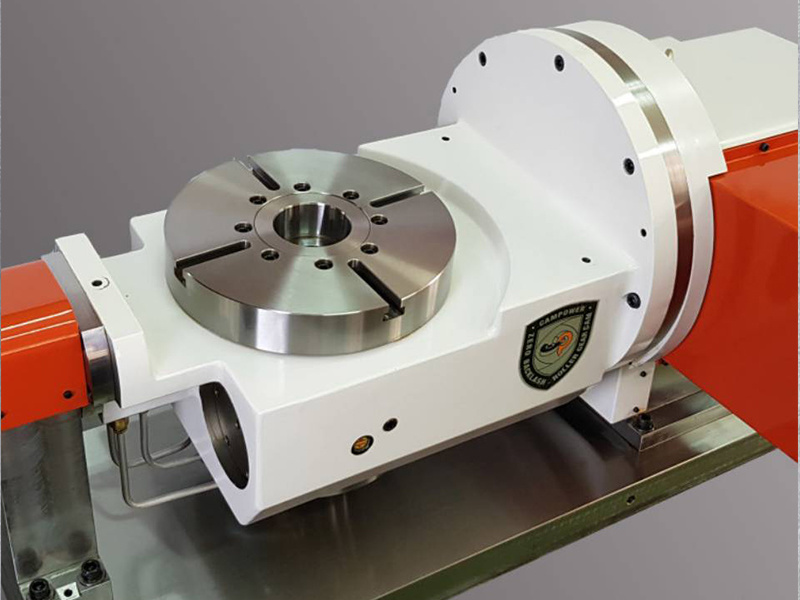

Generally, when the workpiece is not positioned in space, it has six degrees of freedom, three linear displacement degrees of freedom X\Y\Z and three corresponding rotational displacement degrees of freedom A\B\C. The six degrees of freedom are usually expressed by X\Y\Z of the Cartesian rectangular coordinate system to express the three linear axes, and the corresponding A\B\C are used to express the three rotation axes . For example, when designing multi-axis CNC machine tools, that is, machining centers, the number of axes needs to be set according to the planning of the processing object. The more common one on the market is the three-axis CNC machining center, which has three linear displacement axes X\Y\Z. The so-called four-axis machining center generally adds a rotating axis, usually called the fourth axis. Generally, they are angle heads and turntables.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Generally, when the workpiece is not positioned in space, it has six degrees of freedom, three linear displacement degrees of freedom X\Y\Z and three corresponding rotational displacement degrees of freedom A\B\C. The six degrees of freedom are usually expressed by X\Y\Z of the Cartesian rectangular coordinate system to express the three linear axes, and the corresponding A\B\C are used to express the three rotation axes . For example, when designing multi-axis CNC machine tools, that is, machining centers, the number of axes needs to be set according to the planning of the processing object. The more common one on the market is the three-axis CNC machining center, which has three linear displacement axes X\Y\Z. The so-called four-axis machining center generally adds a rotating axis, usually called the fourth axis. Generally, they are angle heads and turntables.

According to ISO regulations, when describing the motion of CNC machine tools, a right-handed rectangular coordinate system is used; the coordinate axis parallel to the main axis is defined as the z-axis, and the rotation coordinates around the x, y, and z axes are A, B, and C respectively. The movement of each coordinate axis can be realized by the workbench or the movement of the tool, but the direction is defined by the movement direction of the tool relative to the workpiece. Usually five-axis linkage refers to the linear interpolation motion of any five coordinates among x, y, z, A, B, and C.

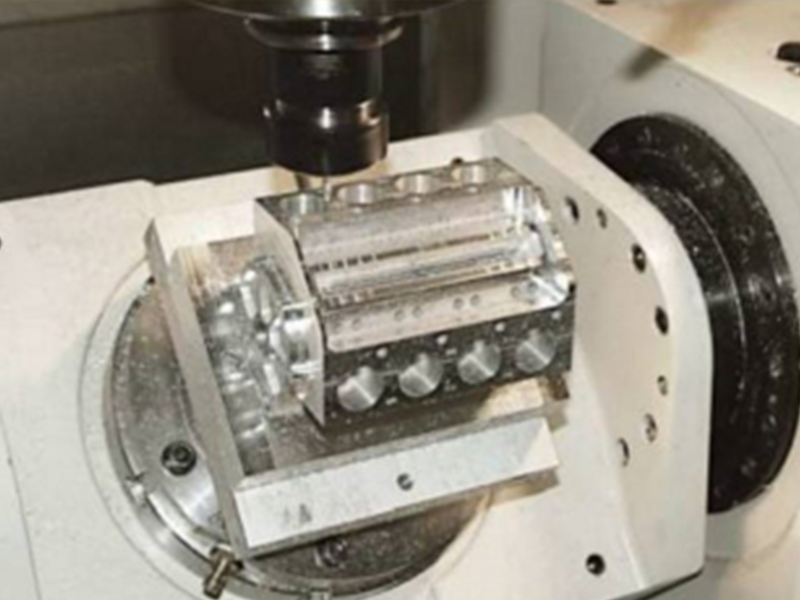

In other words, five axes refers to the three moving axes of x, y, and z plus any two rotation axes . Compared with the common three-axis (x, y, z three degrees of freedom) machining, five-axis machining means that when processing parts with relatively complex geometric shapes, the machining tool needs to be able to position and connect in five degrees of freedom.

Nanjing Jianchuanshi Industry and Trade Co., Ltd. specializes in transforming machine tools from 3-axis to 4-axis and 5-axis machining. Welcome to call us for consultation.

The machine tools used in five-axis machining are often called five-axis machine tools or five-axis machining centers. Five-axis machining is often used in the aerospace field to process body parts, turbine parts and impellers with free-form surfaces . The five-axis machine tool can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

Nanjing Jianchuanshi Industry and Trade Co., Ltd. specializes in transforming machine tools from 3-axis to 4-axis and 5-axis machining. Welcome to call us for consultation.

Related Products

Related Cases

Welcome your message consultation