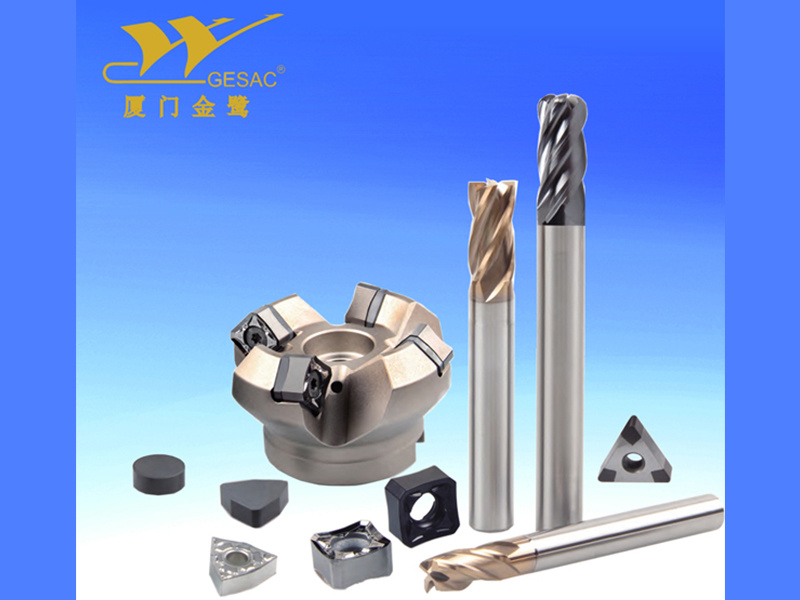

Turning blade

Our company specializes in cutting tools for more than ten years! Many agent brands: Sandvik; Kennametal; YG-1; WALTER; GESAC; YESTOOL; TT ; Zhengheyuan (SYIC) and other advantageous channels: SCHUNK, HAIMER, Seco, ISCAR, DOMA , Nikken and many European and American products; In addition: our company undertakes drill bits, drill tips, milling cutter mold modifications, and coatings, non-standard customization and program design, sales services such as fixtures, jigs, and measuring tools. Excellent quality! Price guaranteed! Delivery time guaranteed! Welcome to come for consultation.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Turning is generally divided into two categories: rough turning and fine turning (including semi-finishing turning). Rough turning strives to use large cutting depth and large feed amount to improve turning efficiency without reducing the cutting speed, but the machining accuracy can only reach IT11, and the surface roughness is Rα20~10 microns; semi-finishing turning and finishing turning Try to use high speed and small feed amount and cutting depth, the processing accuracy can reach IT10~7, and the surface roughness is Rα10~0.16 microns .Using finely ground diamond turning tools on high-precision lathes to finish turning non-ferrous metal parts at high speed can achieve a processing accuracy of IT7~5 and a surface roughness of Rα0.04~0.01 microns. This kind of turning is called " mirror turning". If concave and convex shapes of 0.1 to 0.2 microns are polished on the cutting edge of a diamond turning tool, the turned surface will produce minimally uneven and neatly arranged stripes, which will show a brocade-like luster under the action of light diffraction. As a decorative surface, this type of turning is called "rainbow turning."

Turning characteristics

1. It is easy to ensure the position accuracy of each processing surface of the workpiece

a For example, it is easy to ensure the coaxiality requirements

Use the chuck to install the workpiece, and the rotation axis is the rotation axis of the lathe spindle

Use the front and rear ejector pins to install the workpiece. The axis of rotation is the center line connecting the two ejector pins.

b It is easy to ensure the perpendicularity between the end face and the axis required by the horizontal slide guide rail and the perpendicularity with the workpiece rotation axis.

2. The cutting process is relatively smooth, avoiding inertial force and impact force, allowing larger cutting amounts and high-speed cutting, which is beneficial to improving productivity.

3. Suitable for finishing of non-ferrous metal parts

When the surface roughness of non-ferrous metal parts is large and the Ra value is small, grinding is not suitable and turning or milling is required. High quality can be achieved when using diamond turning tools for fine turning.

4. Simple tools

Turning tools are easier to manufacture, sharpen and install.

Our company specializes in cutting tools for more than ten years!

Many agent brands:

Sandvik; Kennametal; YG-1; WALTER; GESAC; YESTOOL; TT ; Zhengheyuan (SYIC) and other

advantageous channels: SCHUNK, HAIMER, Seco, ISCAR, DOMA , Nikken and many European and American products;

In addition: our company undertakes drill bits, drill tips, milling cutter mold modifications, and coatings, non-standard customization and program design, sales services such as fixtures, jigs, and measuring tools.

Excellent quality! Price guaranteed! Delivery time guaranteed! Welcome to come for consultation.

Related Products

Related Cases

Welcome your message consultation