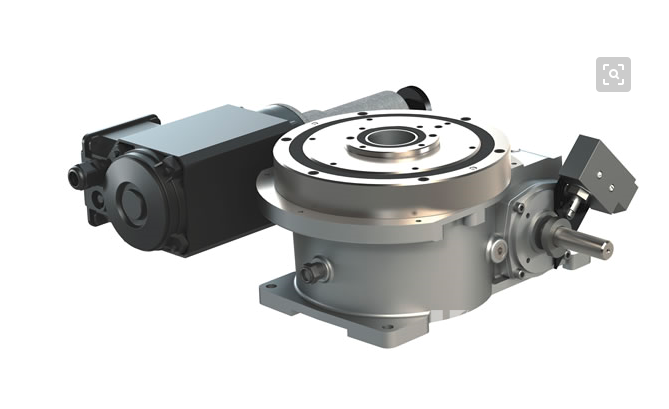

Pneumatic clamping fixture

During pneumatic clamping, the pneumatic clamping device uses compressed air as the power source to push the clamping mechanism to clamp the workpiece. At present, it is mainly used in floor-standing electronic universal testing machines. The commonly used cylinder structures are piston type and membrane type. Piston cylinders are classified into three types according to the cylinder clamping method: fixed, swing and rotary. According to the working mode, they are divided into two types: one-way action and two-way action. The most widely used is the double-action fixed cylinder.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

During pneumatic clamping, the pneumatic clamping device uses compressed air as the power source to push the clamping mechanism to clamp the workpiece. At present, it is mainly used in floor-standing electronic universal testing machines. The commonly used cylinder structures are piston type and membrane type. Piston cylinders are classified into three types according to the cylinder clamping method: fixed, swing and rotary. According to the working mode, they are divided into two types: one-way action and two-way action. The most widely used is the double-action fixed cylinder.

1. The pneumatic transmission responds quickly and moves quickly (the average movement speed of the piston or cylinder is generally 0.5~1m/s, and can reach 10 m/s at high speed). Therefore, in production, the auxiliary time is short and the production efficiency is high.

2. The transmission circuit is simple, easy to operate, and the system is easy to maintain.

3. It has strong adaptability to the working environment and can work reliably in environments that are flammable, explosive, strong magnetism, radiation, moisture, vibration and temperature changes, and is safe to use.

4. Using air as the medium, the energy supply is convenient. Discharge into the atmosphere after use, no need for pipelines and recovery devices

5. Since the compressed air is easily supplied and transported over long distances, it is convenient for centralized control, program control and overload protection.

6. The medium is clean and leakage will not cause pollution.

Related Products

Related Cases

Welcome your message consultation