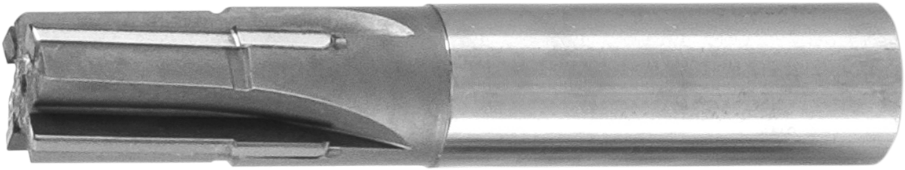

Special PCD precision milling cutter for scroll disk

The core working component of the compressor is the movable and static scrolls. During the operation of the scroll compressor, the compressed air mainly relies on the periodic rotation of the movable disc and the interaction between the static disc. In order to ensure the efficient and stable operation of the parts, the inner workings of the scroll are required. The outer wall surface finish, verticality, and vortex groove profile have very high requirements, which in turn places extremely high requirements on the cutting tools for processing such parts.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

The core working component of the compressor is the movable and static scrolls. During the operation of the scroll compressor, the compressed air mainly relies on the periodic rotation of the movable disc and the interaction between the static disc. In order to ensure the efficient and stable operation of the parts, the inner workings of the scroll are required. The outer wall surface finish, verticality, and vortex groove profile have very high requirements, which in turn places extremely high requirements on the cutting tools for processing such parts.

The performance of scroll plate finishing milling cutters commonly used in the market currently does not meet the requirements. For example, the high price brings high cost pressure on customers, the delivery time is too long, etc. In addition, the scroll plate products have various sizes and models, and the blank die-casting allowance is large. Uneven factors also pose challenges for cutting tools. In order to meet the needs of customers in the industry, improve the service life of finishing tools, and reduce processing costs, Belemstone has established a special R&D team to cooperate with customers in optimizing and upgrading existing tools. For this reason, Belemstone launched a special welded PCD precision milling cutter, which met customers' requirements for improving efficiency and reducing costs, and was recognized by customers.

Belemstone’s customized PCD precision milling cutter for aluminum alloy scrolls has high precision in forming surface contours.

The special PCD material for scroll materials is selected to ensure long processing life.

PCD welding process, lower cost.

Application parameters:

Part name: Scroll

Part material: ADC12 (die-cast aluminum alloy)

Material hardness: HB80

Cutting depth: 15mm

Cutting width: 0.06mm

Machine tool: vertical machining center

Tool handle: Hydraulic handle

Cooling: external cooling

Tangential speed: Vc=328m/min

Feed: Fn=0.1mm/r

Tool life: 7800 pieces

Related Products

Related Cases

Welcome your message consultation