Vortex cooler

Vortex tube cooler is also called cold air tube, vortex cooler, local cooler, vortex tube cold air gun, and dry cooler. The cooling gun is a portable cold air source that is widely used in mechanical drying or point refrigeration and other processes.

Key words:

Classification:

Key words:

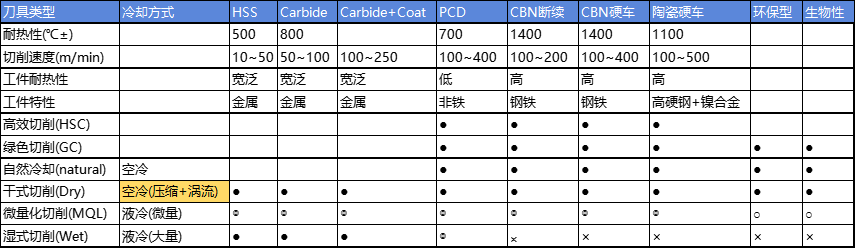

Tool matrix-Fixture matrix

Product Description

Vortex tube cooler is also called cold air tube, vortex cooler, local cooler, vortex tube cold air gun, and dry cooler. The cooling gun is a portable cold air source that is widely used in mechanical drying or point refrigeration and other processes.

Cooling gun features:

√ The cooling gun is a portable cold air source, widely used in mechanical drying or point refrigeration and other processes;

√ The cooling gun can reduce the temperature of the compressed air by 75°F (41°C) using only compressed air to generate low-temperature airflow;

√ The cooling gun is clean and easy to install. Its permanent magnet base and flexible bending tube can send the cold air flow to any location that needs cooling;

√ As long as the air tube is inserted and pointed at the object to be cooled, it can work continuously and stably;

√ Instant on/off;

√ Maintenance-free, no moving parts, no electrical components, and low noise during use (<70 decibels);

√ Uses industrial standard compressed air as the power source, and the cooling capacity is adjustable to avoid freezing during use. The cold air flow and temperature difference can be adjusted as needed to achieve a very excellent cooling effect.

Cold air guns provide cooling applications for critical, harsh industrial environments. The cooling gun is made of very strong stainless steel and is precision machined, assembled and tested under strict quality control. When used in an environment with coolant, water or other corrosive substances, the surface of the cooling gun will not be dented or corroded or rusted.

Cold air gun introduction:

The cold air gun is a cooling equipment suitable for factory applications made using the eddy current cooling principle. The cooling gun's cooling range is capable of reducing the temperature of compressed air from an inlet temperature of 140°F (77°C) to 75°F (41°C). Because the compressed air temperature is close to the ambient temperature, it can reduce the compressed air with an ambient temperature of 75°F to a cooling air flow of 0°F (-18°C) through decompression.

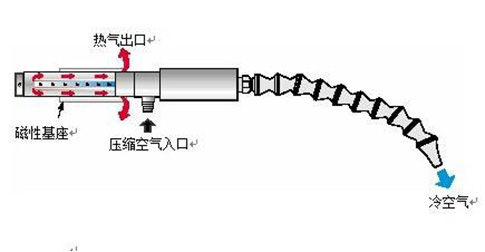

Working principle of cold air gun vortex:

The cooling gun uses a vortex tube to turn ordinary compressed air into two low-pressure airflows, hot and cold. The hot gas flow is reflected by the suppressor and is partially discharged from the hot gas outlet. The cold air flow is discharged from the universal hose, and the flexible tube is directed to the parts that need to be cooled, immediately cooling the heating components. The cooling gun comes with a magnetic base, making it very easy to install and very lightweight.

◆ No coolant, zero chemical loss or residue to replace emulsion and oil coolant;

◆ Cooling solder joints, hot melt metal, thermal adhesive;

◆ Cooling electronic components, circuit boards and temperature regulating devices for heat detection;

◆ Assembly of cooling and heat-fitting parts;

◆ Cooling hot mold, ultrasonic device;

◆ Cool the sewing needle to prevent thread breakage and avoid breakage of synthetic yarn caused by heat.

The cooling gun is a very energy-saving tool:

● Cooling and drying equipment for metal, composite, plastic, rubber and wood processing industries.

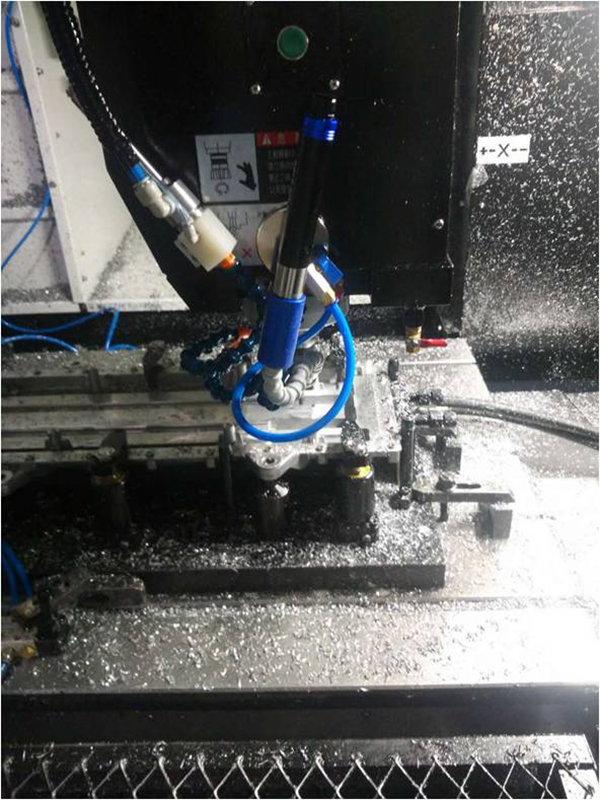

● Especially suitable for tapping operations in machining workshops, as well as CNC machining centers, CNC turning centers, ordinary turning grinders, milling machines and ideal tools for workpiece cooling. It can be widely used for turning, milling, grinding, planing, drilling, and tapping. , complete the processing of parts cleanly and dryly.

● Enhance the workpiece feed, moving speed and improve workpiece quality.

● No consumption of coolant, avoid contamination caused by coolant, irritate the skin, and stain the walls and floors of the machine.

● Improve the service life of tools, improve yield, improve finish, and reduce work differences.

● To avoid micro-cracks and heat generation in the product, the cold air gun can produce clean low-temperature airflow that is -28°C lower than the compressed air temperature.

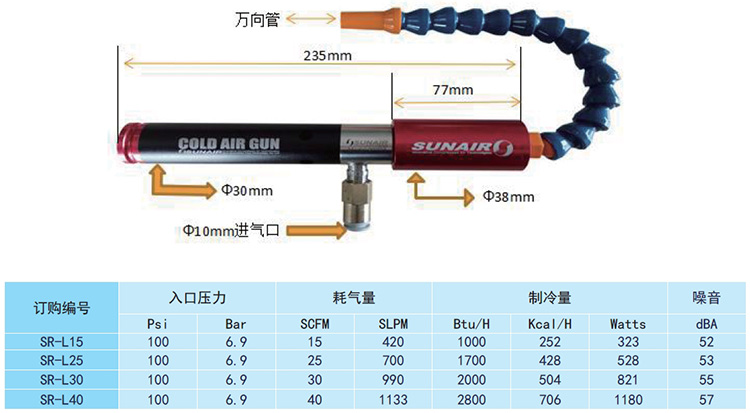

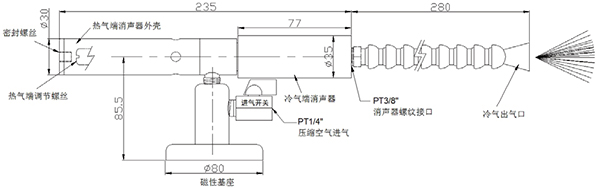

Cooling gun dimensions:

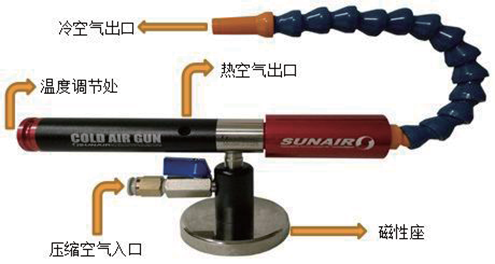

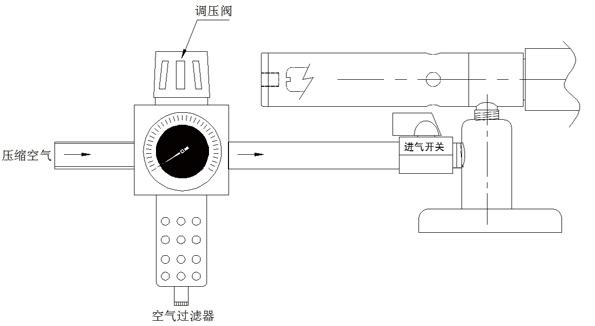

Cooling gun installation:

■ Attach the cooling gun to the magnetic base.

■ Connect the cold air outlet to a universal tube.

■ Connect the compressed air inlet to the air source, the air source pressure is 4-9Bar.

■ Control the start/stop of the cooling gun through the ball valve switch on the base.

■ PT1/8 is the window for adjusting the cooling capacity. First, completely unscrew the PT1/8 screw, and then use a flat-blade screwdriver to turn it clockwise. The cooling capacity will increase, and vice versa.

Remember not to tighten the adjusting screw! Otherwise, the cooling effect will not be achieved.

Cooling gun application:

It is mainly used for high-efficiency machining or situations where cutting fluid is not suitable.

like:

Superhard machining of automobile (chassis) parts,

CBN intermittent superhard turning, spline shaft finishing,

CBN superhard milling, ball cage processing,

pump valve parts,

engineering machinery, plunger pump cylinder, boring cutter, slurry

pump rotor, waist-type oil tank Ceramic turning and more

Through the application of eddy current cooling technology in machining, compared with traditional dry cutting machine tools, the temperature of the workpiece processing part is reduced by about 50%, reducing deformation caused by cutting heat, reducing cutting stress, and avoiding iron chips due to poor chip removal. Scratches and other phenomena caused to the workpiece have improved the processing quality of the workpiece: after the cutting parameters are optimized, the processing efficiency is increased by about 30% on average, the tool temperature is reduced by about 50%, the tool loss is reduced, and the tool service life is more than doubled.

Applications:

Related Products

Related Cases

Welcome your message consultation