Application of High Pressure Cooling System in Machine Tool

Release time:

2023-05-30

The machine tool high-pressure cooling system is a kind of water pump equipment commonly found on machine tools. Its main function is to supply and transport coolant to the machine tool in time so that it can ensure that it continues to operate within a suitable temperature range. Application effect: 1. High pressure chip breaking and chip punching to avoid winding of iron filings. 2. Good and reliable cooling method can improve tool life, improve cutting parameters, thereby improving production efficiency. 3. Reduce the machine tool downtime caused by winding chips, and effectively improve the machine tool startup rate. 4. For the application of different materials: Mild steel efficiency 20%, life extension 20%; Carbon steel, alloy steel efficiency 20%, life extension 10%; Aluminum alloy, magnesium aluminum alloy efficiency 30%, life extension 30%; Stainless steel, nickel alloy efficiency 40%, life extension 50%.

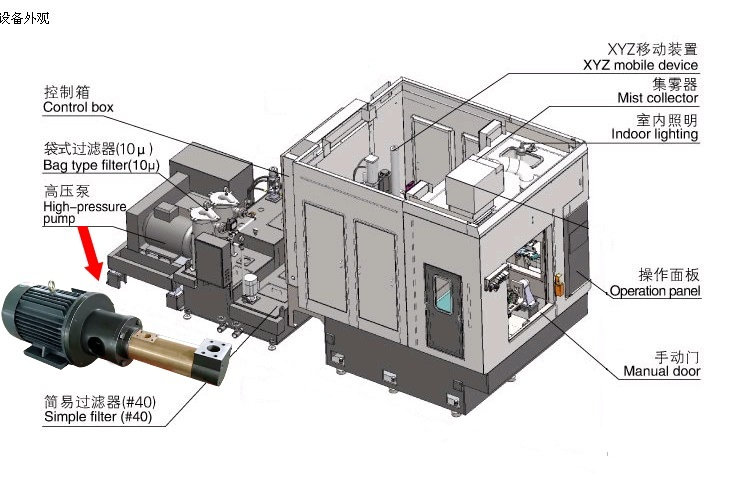

machine tool high pressure cooling system

The machine tool high-pressure cooling system is a kind of water pump equipment commonly found on machine tools. Its main function is to supply and transport coolant to the machine tool in time so that it can ensure that it continues to operate within a suitable temperature range.

Equipment composition:

Market Application:

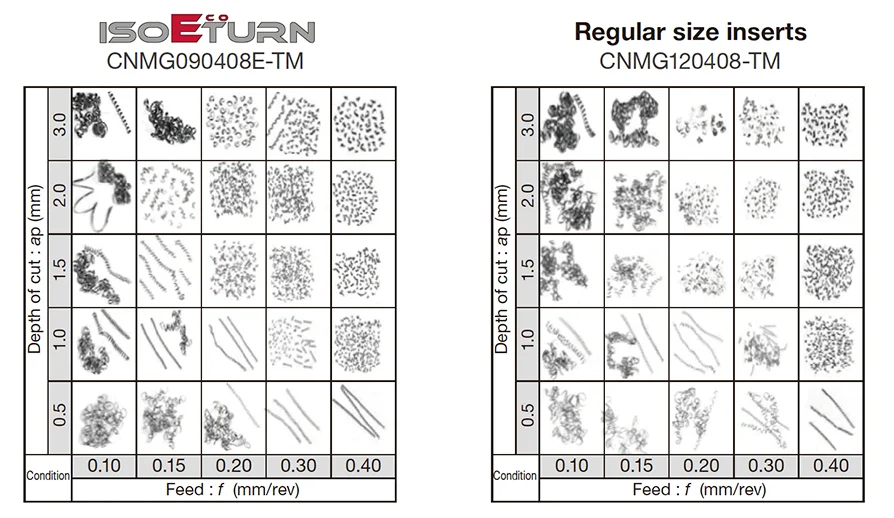

More than 75% of the turning market only uses a cutting depth of less than 3 mm in the selection of roughing, semi-finishing and finishing cutting depth, thus the chip breaking problem of iron filings has always been a difficult problem in machining.

The emergence of high-pressure cooling of machine tools has greatly and effectively solved this problem. Especially for heat-sensitive low melting point materials (aluminum, magnesium, aluminum-magnesium alloy, pure aluminum, aluminum alloy, aluminum alloy casting materials, high silicon aluminum alloy) viscous materials, materials with relatively high elastic modulus (nickel alloy, stainless steel, etc.) rebound, extrusion, chip accumulation, wear resistance and cutting hardening. High pressure internal cooling is one of the best choices.

Typical relationship between turning depth ap(mm) and feed f(mm/rev)

The amount of difference between internal cooling and regular

Application effect:

1. High pressure chip breaking and chip punching to avoid winding of iron filings.

2. Good and reliable cooling method can improve tool life, improve cutting parameters, thereby improving production efficiency.

3. Reduce the machine tool downtime caused by winding chips, and effectively improve the machine tool startup rate.

4. For the application of different materials:

Mild steel efficiency 20%, life extension 20%; Carbon steel, alloy steel efficiency 20%, life extension 10%; Aluminum alloy, magnesium aluminum alloy efficiency 30%, life extension 30%; Stainless steel, nickel alloy efficiency 40%, life extension 50%.

Product sequence selection for high-pressure cooling systems:

1. High pressure internal cold pump

2. High-pressure internal cooling tool system

3. High-pressure internal cooling accessories and consumables (cooling pipe, closed collet, nozzle)

4. High-pressure internal cooling cutting tool (blade, hard)

5. Product selection (coating selection, internal cooling mode selection)

6. Process

7. Safety and protection related

8. Semi-automation, automation, black light factory support.

9. Capture the world's leading technology to provide high-speed and fast-acting Chinese solutions.

Application Machine Tools:

Yamazaki Mazak (Yamazaki Mazak)

LG MazaK (Little Giant)

DMG (Demage)

OKUMA (Okuma)

MAKINO

CHIRON (Wave)

DN Solutions(迪恩)

DOOSAN

Related News