Thread turning

There are many types of threads, which can be divided into connecting threads and transmission threads according to their uses; they can be divided into triangular threads, square threads, saw-shaped threads, and circular threads according to their tooth shapes; they can be divided into right-hand threads according to their spiral directions. Spiral threads and left-hand threads; divided into single-thread threads and multi-thread threads according to the number of spiral threads. According to the shape of the parent body, it can be divided into cylindrical thread and conical thread.

Key words:

Classification:

Key words:

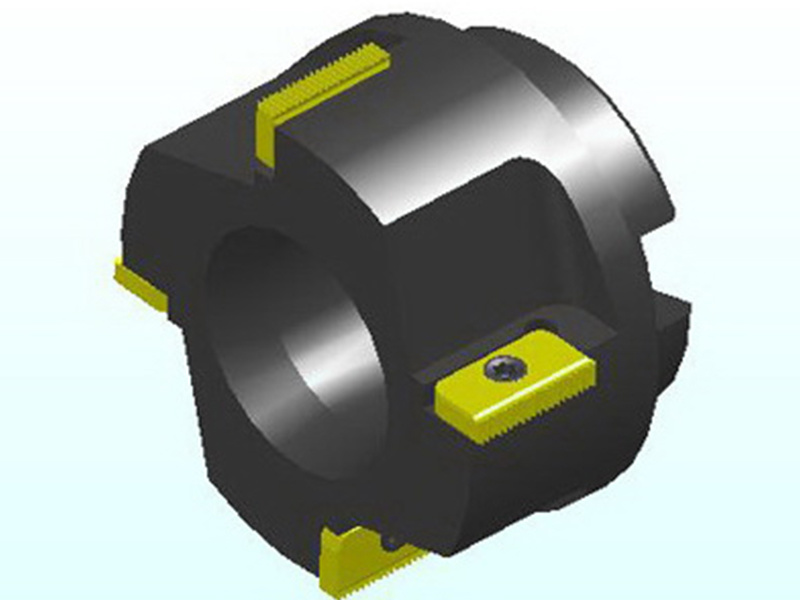

Tool matrix-Fixture matrix

Product Description

There are many types of threads, which can be divided into connecting threads and transmission threads according to their uses; they can be divided into triangular threads, square threads, saw-shaped threads, and circular threads according to their tooth shapes; they can be divided into right-hand threads according to their spiral directions. Spiral threads and left-hand threads; divided into single-thread threads and multi-thread threads according to the number of spiral threads. According to the shape of the parent body, it can be divided into cylindrical thread and conical thread.

Thread There are many processing methods, among which turning is the most commonly used processing method. No matter which thread is turned, Lathe spindle and the tool must maintain a strict motion relationship: every time the spindle rotates once (that is, the workpiece rotates once), the tool should move evenly by one Lead distance. The rotation of the workpiece and the movement of the turning tool are both driven by the spindle, thus ensuring a strict motion relationship between the workpiece and the tool.

Nanjing Jianchuanshi Industry and Trade Co., Ltd. mainly sells YG-1, Sandvik, Kennametal, YesTool and other knives and cutting tools; Jianchuanshi Company not only provides high-quality cutting tools, but also provides specialized Production technical guidance. There are many technical engineers in the technical department of Beianshi Company, who will provide you with guidance on every step of the processing process of your products and analyze related technical issues, so that your products will have no worries from raw materials to finished products!

Related Products

Related Cases

Welcome your message consultation