Powder metallurgy tap

Powder metallurgy taps are made of high-speed steel material prepared by advanced powder metallurgy technology. With uniform and dense microstructure, excellent hardness and toughness, they are suitable for high-difficulty processing materials such as quenched steel, stainless steel, titanium alloy, and high-temperature alloy, and accurately overcome the problem of high-strength, high-precision thread processing. Spiral groove / straight groove double structure is optional, covering M2 - M48 full specifications, widely used in automotive, aerospace, mold, high-end equipment manufacturing and other fields, providing a stable and efficient processing solution for precision thread forming.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Powder Metallurgy Tap - Precision tool for high-performance threading

Product core keywords

Powder metallurgy tap, high-performance tap, precision thread processing, wear-resistant tap, multi-material compatible tap, high-precision tapping tool

Product overview

The powder metallurgy tap is made of high-speed steel material prepared by advanced powder metallurgy technology, with uniform and dense microstructure, excellent hardness and toughness, and is suitable for Quenched steel, stainless steel, titanium alloy, high-temperature alloy and other difficult-to-machine materials, accurately solving the problem of high-strength and high-precision thread processing. Spiral groove / straight groove double structure is optional, covering M2 - M48 full specifications It is widely used in automobiles, aerospace, molds, high-end equipment manufacturing and other fields, providing stable and efficient processing solutions for precision thread forming.

Core advantages

1. Powder metallurgy material: performance breakthrough tradition

- Super wear-resistant matrix : Select PM20/PM30 powder metallurgy high-speed steel , density > 98%, hardness up to 66 - 68HRC , the wear resistance is improved compared with traditional high-speed steel taps 80% , when processing quenched steel (HRC58 - 62) and stainless steel (304/316L), the life of a single tap is extended to 500 - 1000 holes (ordinary taps are only 100 - 300 holes).

- Strong toughness balance : Powder metallurgy's unique grain refinement process improves the impact toughness of the tap 40% , the ability to resist chipping and fracture is significantly enhanced, adapted to Intermittent cutting, deep hole tapping and other complex working conditions (such as deep blind hole thread processing of molds, stable processing is still possible when the hole depth is ≥8D).

2. Precision thread forming: tolerance is accurate and controllable

- Micron-level precision grinding of cutting edges : Using Laser dressing technology , the cutting edge accuracy is controlled at **±0.005mm**, and the thread tolerance is stable up to ISO 3H/5H level (Ordinary taps are mostly 6H level), which meets the strict requirements of automobile engine cylinder heads (aluminum alloy M8×1.25 thread, tolerance ±0.01mm) and aerospace titanium alloy structural parts (M6×1 thread, tolerance ±0.008mm).

- Coating customization optimization :

- Processing stainless steel / high temperature alloy: select AlCrN coating , the friction coefficient is ≤0.2, the high temperature resistance is 600℃, reducing the adhesion of cutting heat, and the thread surface roughness Ra≤0.8μm ;

- Processing titanium alloy / aluminum alloy: select TiAlN coating , improve lubricity, avoid material sticking to the knife, and adapt to high-precision, high-finish requirements (such as aluminum alloy threads for medical equipment, Ra≤0.6μm).

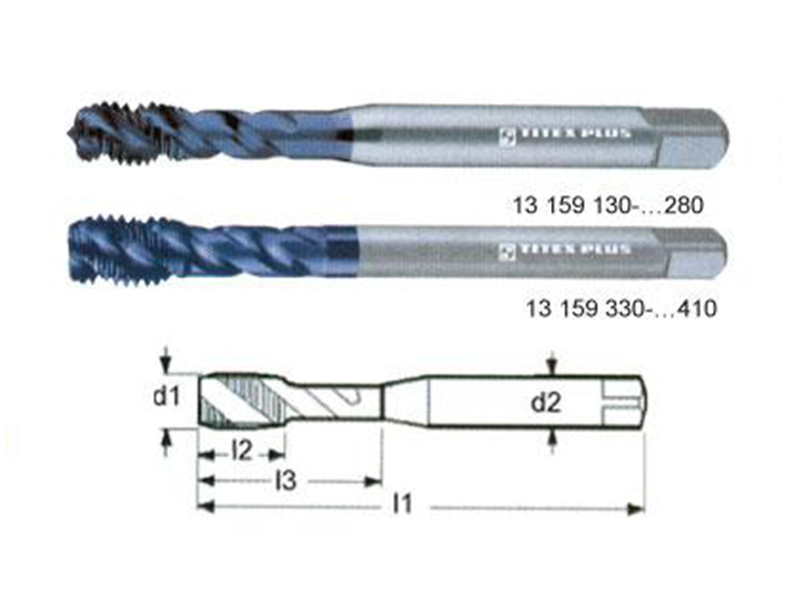

3. Multi-scene adaptation: flexible structure customization

- Groove type and helix angle are optional :

- Spiral groove (35° - 45°): suitable for Blind hole machining , the chips are discharged orderly out of the hole along the groove to avoid clogging (such as aerospace deep blind hole threads, efficient chip removal is still possible when the hole depth is 50mm);

- Straight groove (0° narrow groove width): strengthen rigidity, adapt to Through holes, high-hardness materials (Such as quenching die steel HRC60 tapping, the ability to resist chipping is increased by 30%).

- Shank and cooling customization : Provide Straight shank, Morse taper shank, internal cooling hole shank , suitable for automatic lathes, CNC machining centers, radial drills and other equipment; internal cooling hole shank can achieve High-pressure cooling oil directly to the cutting area , reduces the cutting temperature by 30% when machining titanium alloys, extending the life of the tap.

Technical parameters

| Project | Parameter range | Standard configuration | Optional customization |

|---|---|---|---|

| Applicable materials | Quenched steel (HRC50 - 62), stainless steel, titanium alloy, high-temperature alloy | General type (PM20+AlCrN) | Titanium alloy special type (PM30+TiAlN) |

| Thread accuracy | ISO 3H, 5H, 6H/6HS | ISO 6H (default) | Customizable ISO 3H (ultra-high precision requirements) |

| Helix Angle (Spiral Flute) | 35° - 45° | 35° (conventional blind hole) | 45° (deep blind hole, hole depth ≥8D) |

| Shank Type | Straight shank, internal coolant hole shank | Straight shank (M2 - M24) | Extended straight shank (M24 - M48, suitable for deep holes) |

| Recommended cutting parameters | Quenched steel: n≤30rpm, f=0.8 - 1mm/r; Aluminum alloy: n=80 - 120rpm, f=1 - 1.5mm/r |

General parameters (suitable for most materials) | Customize exclusive parameters according to material / equipment (e.g., titanium alloy n=40 - 60rpm) |

Application scenarios and cases

1. Automotive manufacturing: Engine cylinder head thread processing

- Demand : Aluminum alloy cylinder head M8×1.25 thread, batch of 100,000 pieces / month, requiring thread accuracy 5H, surface Ra≤1.0μm, equipment is CNC machining center.

- Solution Select PM20 powder metallurgy tap (35° spiral flute + AlCrN coating) , with MQL micro-lubrication (cutting fluid consumption reduced by 70%), single tap processing ≥8000 holes (ordinary tap only 3000 holes), efficiency increased by 50%, thread defect rate decreased from 3% to 0.5%.

2. Aerospace: Titanium alloy structural parts thread forming

- Demand : Titanium alloy TC4 M6×1 thread, hole depth 20mm blind hole, accuracy 3H, surface Ra≤0.8μm, equipment is five-axis machining center.

- Solution Select PM30 powder metallurgy tap (45° large spiral flute + TiAlN coating + internal cooling hole shank) , high-pressure cooling oil (pressure 50bar) directly to the cutting area, speed 40rpm, feed rate 0.8mm/r, single tap processing ≥600 holes, thread accuracy stable ±0.008mm, to meet the high reliability connection needs of aerospace.

3. Mold processing: Quenched mold steel thread repair

- Demand : Mold steel HRC60 M10×1.5 thread hole repair (original tap chipping scrapped), hole depth 30mm blind hole, requiring rapid repair, accuracy 5H.

- Solution Select PM20 straight flute tap (0° narrow groove width + steam treatment strengthening) , speed 20rpm, feed rate 0.6mm/r, with sulfur-containing extreme pressure cutting oil, single tap repair thread hole ≥300, repaired thread tolerance ±0.015mm, mold delivered 3 days in advance.

Precautions for use

- Clamping accuracy : Must use high-precision tapping chuck (runout ≤0.01mm), to avoid tap breakage and thread accuracy exceeding the tolerance due to poor concentricity (such as processing aerospace high-precision threads, concentricity difference of 0.02mm, thread tolerance may exceed ±0.015mm).

- Cutting parameter matching :

- High hardness material (quenched steel HRC60): Low speed (≤30rpm) + small feed rate (0.5 - 0.8mm/r) , to avoid impact chipping;

- Soft material (aluminum alloy / titanium alloy): Medium to high speed (80 - 150rpm) + adaptive feed , improve efficiency (such as aluminum alloy M6 tapping, speed 120rpm, feed rate 0.7mm/r, efficiency increased by 40%).

- Cooling and cleaning : Clean the residual chips on the tap cutting edge in time after processing (can be cleaned with ultrasonic cleaning machine + special cleaning agent), to avoid chip adhesion affecting the next use; long-term storage needs to be coated with anti-rust oil, moisture-proof and rust-proof (especially powder metallurgy material, improper rust prevention is easy to reduce coating adhesion).

Frequently Asked Questions (Q&A)

Q1 : Powder metallurgy taps are more expensive than ordinary taps, how about the cost performance?

Answer : Although the purchase cost is 30% - 50% higher, the life is increased by 2 - 3 times (such as quenched steel processing, the life of ordinary taps is 100 holes, powder metallurgy can reach 300 - 500 holes), and the scrap rate is reduced due to high precision (such as automobile engine cylinder head threads, the scrap rate is reduced from 5% to 1%), comprehensive processing cost Reduced by 20% - 30% , especially suitable for medium and high volume, high precision demand scenarios.

Q2 : The tap is easy to stick to the knife and the thread is rough when processing titanium alloy, how to solve it?

Answer : Need 3 aspects of optimization:

- Tap: Select PM30 material + TiAlN coating , improve lubricity;

- Parameters: Low speed (40 - 60rpm) + adapted feed (0.6 - 0.8mm/r) , reduce cutting heat;

- Cooling: Use Cutting fluid for titanium alloys (concentration 15% - 20%) or high-pressure cooling oil to remove cutting heat in time. With the combination of the three, the probability of sticking is reduced by 80%, and the thread roughness can reach Ra≤0.8μm.

Q3 : After the powder metallurgy tap breaks, can it be repaired and continue to be used?

Answer : If the chipping range is small (≤1 tooth), it can be Professional sharpening repair (remove the chipped part, re-grind the cutting edge and calibration part), and re-coat the coating to restore 70% - 80% performance; if the chipping is serious (≥2 teeth), it is recommended to replace it to avoid affecting the thread accuracy.

Take Action Now: Get Your Exclusive Plan

Click the button below to submit your Processing materials, thread specifications, equipment type , professional engineers 1v1 customization:

✅ Free cutting parameter table (adapted to your equipment and materials)

✅ Tap selection report (including groove type, coating, shank recommendation)

✅ Machining cost calculation (compare with existing solutions, cost reduction space visualization)

Powder metallurgy tap - makes high-difficulty thread processing more stable and efficient. Click to start a new experience in precision manufacturing!

Related Products

Related Cases

Welcome your message consultation