Vacuum clamp

A vacuum refers to a space without any matter. But in fact, we usually refer to a space where the air pressure is less than atmospheric pressure as a vacuum. Vacuum clamping systems are commonly used to quickly clamp wood, plastics and non- ferrous metals. They are compatible with CNC machines . Here, vacuum clamping is mainly used for special processing systems; for example, clamping one side of an aluminum plate and processing the other five sides. This increases throughput and reduces costs: the vacuum gripper does not damage the clamping surfaces and eliminates the need for time-consuming and laborious alignment of the workpieces. The latest vacuum clamping system can realize the rapid replacement of workpieces of different specifications and shapes. In vacuum clamping, the workpiece is firmly pressed against the workbench by the atmospheric pressure outside it. Rather than "sucking" on the workbench as is commonly thought. The lateral force that the workpiece can withstand is mainly determined by the surface structure, air pressure difference and contact area. The larger the contact area, the greater the clamping force. Vacuum clamps can be applied to clamp non-magnetic materials, such as aluminum, copper, alloys and other non-ferrous metals, and plastics, wood and other polymer materials .

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

A vacuum refers to a space without any matter. But in fact, we usually refer to a space where the air pressure is less than atmospheric pressure as a vacuum. Vacuum clamping systems are commonly used to quickly clamp wood, plastics and non- ferrous metals . They are compatible with CNC machines . Here, vacuum clamping is mainly used for special processing systems; for example, clamping one side of an aluminum plate and processing the other five sides. This increases throughput and reduces costs: the vacuum gripper does not damage the clamping surfaces and eliminates the need for time-consuming and laborious alignment of the workpieces.The latest vacuum clamping system can realize the rapid replacement of workpieces of different specifications and shapes. In vacuum clamping, the workpiece is firmly pressed against the workbench by the atmospheric pressure outside it. Rather than "sucking" on the workbench as is commonly thought. The lateral force that the workpiece can withstand is mainly determined by the surface structure, air pressure difference and contact area. The larger the contact area, the greater the clamping force. Vacuum clamps can be applied to clamp non-magnetic materials, such as aluminum, copper, alloys and other non-ferrous metals, and plastics, wood and other polymer materials .

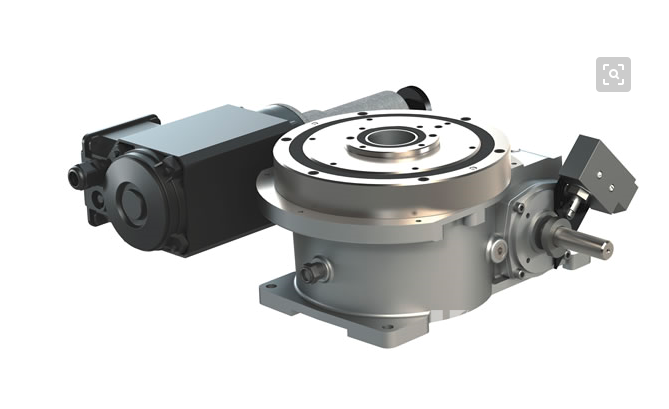

Related Products

Related Cases

Welcome your message consultation