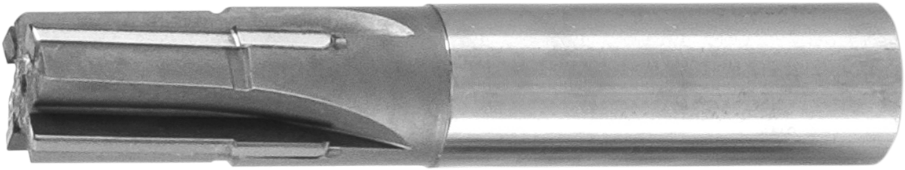

Graphite milling cutter

Graphite milling cutters are diamond-coated milling cutters used in modern industry to process graphite, alloy and non-ferrous materials.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Graphite milling cutters are diamond-coated milling cutters used in modern industry to process graphite, alloy and non-ferrous materials.

composition

1. Coarse-grained tungsten steel substrate (1-6UM), because the diamond coating has coarser particles (divided into coarse and fine coatings and nano-coatings);

2. Cover with 8-12UM single-sided diamond coating.

3. Compared with ordinary milling cutters, the geometric angle of the cutter body is sharper.

Processing range

1. Composite material processing

2.Diamond coating

3.Carbon fiber processing

4. Glass fiber processing

5. Graphite electrode processing

6. High silicon aluminum, silicon carbide processing

7. Ceramic zirconia processing

8. Teeth (zirconia) processing

9. Special processing of graphite, etc.

superiority

Because of its diamond coating, its heat insulation performance is significant, and the superior wear resistance of diamond makes the performance of diamond-coated graphite milling cutters during processing 10-15 times higher than that of ordinary tungsten steel milling cutters. The processing accuracy is higher. It saves tool changing time and avoids the trouble of tool marks caused by multiple tool changes, which greatly saves costs.

technology

Purification and cobalt removal treatment of alloy substrate surface; Murakami reagent (m(K3[Fe(CN)]6)=10 g, m(KOH)=10 g, V(H2O)=100 mL)) etching tungsten carbide phase, and then treat the deep cobalt with acid to improve the diamond deposition quality and adhesion. Diamond coating removal and re-coating technology; CVD method to re-deposit the diamond film on the alloy substrate,

Refine the surface grains and obtain lower surface roughness by polishing the diamond surface. Use arc ion plating equipment to induce arc discharge between the electrode and the cathode metal target, and then coat the diamond in the arc ion plating equipment. When a negative bias voltage is applied to the layer, the surface of the diamond film will be bombarded by metal ions, refining the surface grains to make the surface smooth and reduce roughness.

The coating has good adhesion and strong oxidation resistance (TiAlN, CrAlN, VAlN, etc.), also by optimizing the structure of the diamond-coated drill bit, that is, changing the tool edge shape and film thickness, or by improving the toughness of the diamond coating. To improve adhesion, through testing, it was found that its diamond-coated drill bit has excellent processing efficiency for silicon-aluminum alloys. Since diamond will be oxidized when processing iron-based materials and heat-resistant materials (titanium alloys) at high temperatures, reducing its cutting efficiency and application fields, by improving the coating structure, first deposit a boron-doped diamond film on the drill bit, and then The PVD method is then used to coat a layer of intermetallic compounds (such as TiAlN, etc.), which effectively improves the oxidation resistance of the tool and extends the life and application field of the tool while ensuring the strength of diamond processing.

Microcrystalline (Fine crystal) and Ultra fine crystal (Ultra fine crystal) diamond coatings with smooth surfaces . Another unique technology of the company is the ability to prepare diamond-coated tools with smooth surfaces. Polishing technology used to refine diamond surface grains can usually obtain a smooth surface, but its application will be limited for tool materials with complex geometric shapes. The grain size can be obtained by controlling secondary nucleation conditions during the deposition of diamond films. Smaller microcrystalline diamond-coated end mills have very small tool surface roughness. Compared with ordinary diamond coatings, they have higher processing accuracy and wear resistance and durability. They are a powerful tool for processing silicon and aluminum materials.

Related Products

Related Cases

Welcome your message consultation