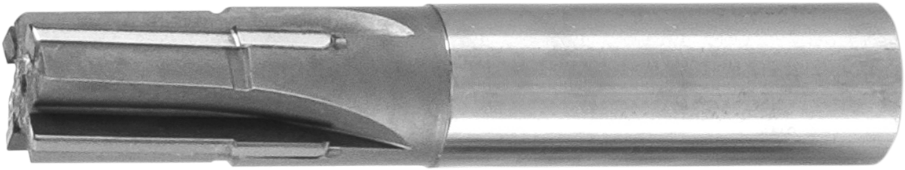

Turbomolecular pump seven-stage impeller

A turbomolecular pump is a vacuum pump that uses a high-speed rotating impeller to transfer momentum to gas molecules, causing the gas to flow in a directional manner and pump the gas.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Turbomolecular pump seven-stage impeller

A turbomolecular pump is a vacuum pump that uses a high-speed rotating impeller to transfer momentum to gas molecules, causing the gas to flow in a directional manner and pump the gas.

The advantages of the turbomolecular pump are fast start-up, resistance to various rays, resistance to atmospheric impact, no gas storage and desorption effects, no or little oil vapor pollution, and the ability to obtain clean ultra-high vacuum. Turbomolecular pumps are widely used in high-energy accelerators, controllable thermonuclear reactors, heavy particle accelerators, and vacuum coating manufacturing processes that require high vacuum.

A turbomolecular pump is mainly composed of a pump body, a rotor with blades (i.e., a moving impeller), a stationary impeller, and a drive system.

The linear speed of the outer edge of the moving impeller is as high as the thermal motion speed of gas molecules (generally 150~400 meters/second). The compression ratio of a single impeller is very small, and a turbomolecular pump consists of more than ten moving impellers and stationary impellers.

Our company specializes in the production and sales of various specifications of special cutting tools and fixtures for seven-stage impellers of turbomolecular pumps.

Full range of processing provided:

1. Process plan;

1.1 μ-level fixture;

1.2 μ-level tool;

1.3 μ-level (stress/heat shrink) tool system;

2. Testing plan

2.1 Dynamic balancing machine;

2.2 Vibration tester;

3. High-pressure internal cooling accessories for high-speed aluminum processing;

Turbomolecular pump seven-stage impeller

Size: φ350*286mm

Material: 7075-T6 aluminum alloy

Related Products

Related Cases

Welcome your message consultation