Digital application smart tool holder

Digitalization is considered the biggest challenge facing the manufacturing industry. But it also brings opportunities for companies to make their processes more precise, more reliable, and faster. The prerequisite for achieving this is that intelligent systems identify unforeseen instabilities and intervene in real time to ensure process stability. The effect is to minimize scrap rates, drastically reduce production times, and significantly increase quality and efficiency – even in small batches.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

Digitalization is considered the biggest challenge facing the manufacturing industry. But it also brings opportunities for companies to make their processes more precise, more reliable, and faster. The prerequisite for achieving this is that intelligent systems identify unforeseen instabilities and intervene in real time to ensure process stability. The effect is to minimize scrap rates, drastically reduce production times, and significantly increase quality and efficiency – even in small batches.

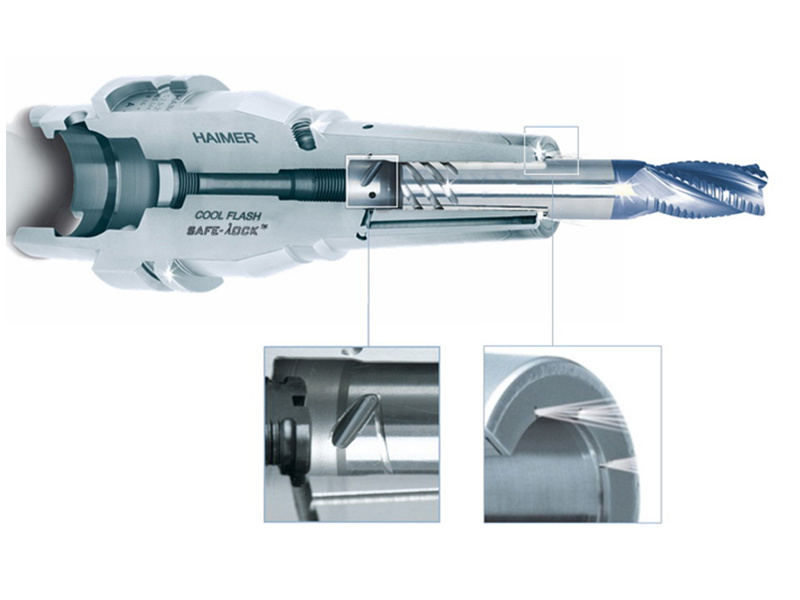

iTENDO² combines the technical features of TENDO hydraulic expansion technology with digital process monitoring. From the metal cutting field, the iTENDO² smart toolholder is considered the non-wearing component “closest to the part” and can therefore be used for signal acquisition.

1. Advantages - Benefits for you

- Intelligent real-time sensor technology

enables easy process monitoring and maximizes tool life - Rotation speed up to 30,000 RPM,

wide application scenarios - 100% compatible

and 1:1 interchangeable with SCHUNK standard toolholders, eliminating the need for time-consuming reprogramming of the system - Three customized packages

to suit all required tasks and solutions of complexity - iTENDO² pad

Higher process transparency, sustainable process optimization, robust process comparison

2. Options and special information

- The aluminum housing provides optimal protection and versatility.

All components are well protected and easily accessible to the machine when process monitoring is required. - iTENDO² pad

- No machine connection required, can be connected directly to the platen

- Show Chatter index (10 Hz data)

- Alerts and trend assessment on tablet

3. Application functions

1. Monitor quality

When countersinking, iTENDO² monitors the surface quality for acceptable quality. In this application, the monitoring of the counterbore process is used for quality and process control, as well as recording characteristics critical to this function.

2.Tool monitoring

With iTENDO², very slight vibrations in tools with diameters as small as Ø 3 mm can also be detected, indicating possible tool breakage due to wear or excessive feed rates. This helps avoid or minimize machine downtime.

3. Optimization process

By comparing the recorded vibration data, we can determine the optimal process settings. This allows us to optimally set parameters and make cutting processes more precise and efficient, an excellent example being thread milling.

Related Products

Related Cases

Welcome your message consultation