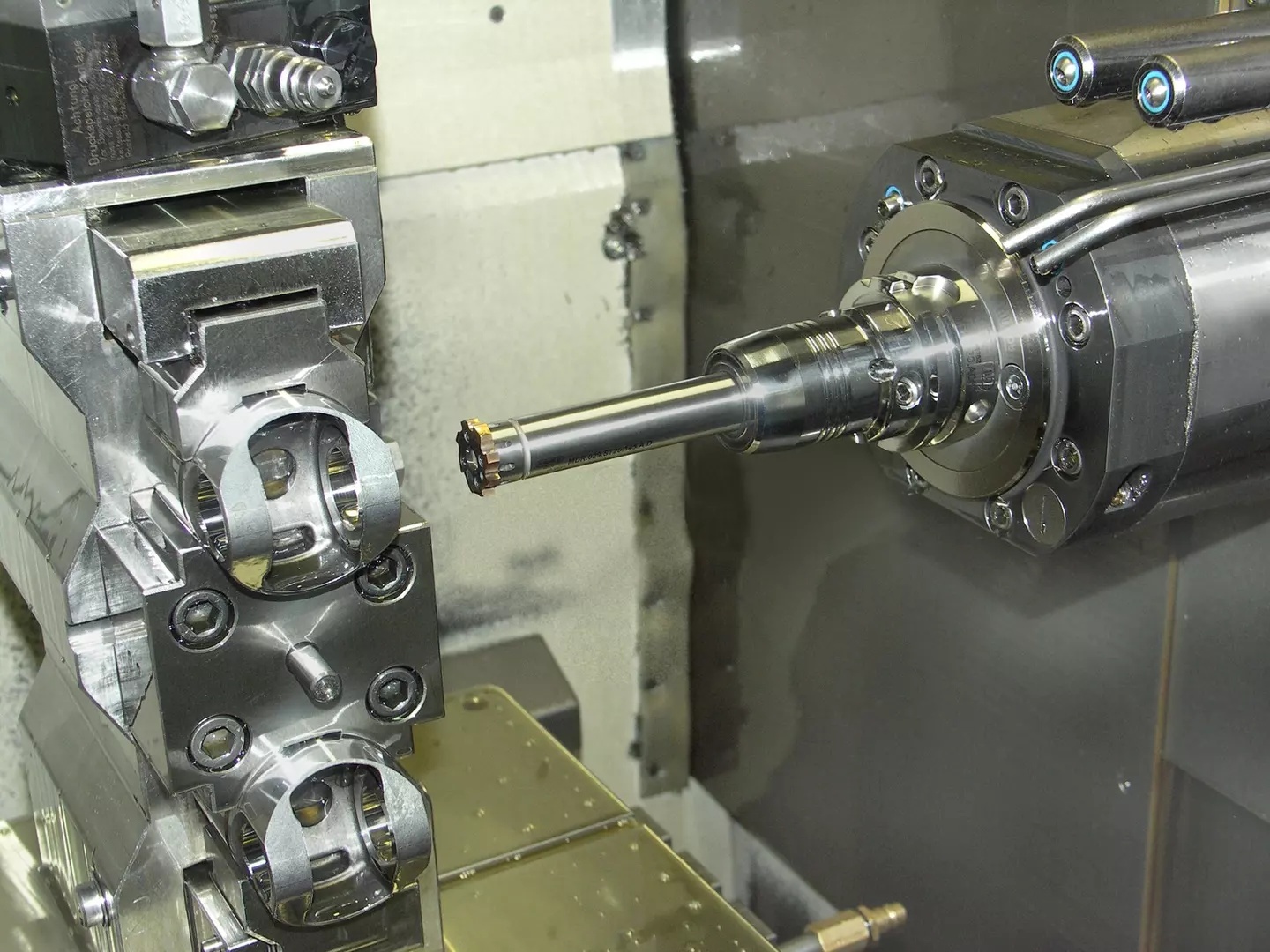

High precision zero adjustment tool holder

TENDO Zero hydraulic toolholders are specialized toolholders suitable for high-precision drilling, reaming or precision boring, i.e. where very high precision is required. Minimum concentricity errors can be achieved for the tool, interface and spindle that will be compensated separately.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

High precision zero adjustment tool holder

TENDO Zero hydraulic toolholders are specialized toolholders suitable for high-precision drilling, reaming or precision boring, i.e. where very high precision is required. Minimum concentricity errors can be achieved for the tool, interface and spindle that will be compensated separately.

advantage

- Standard precision dynamic balancing

is suitable for high-speed and HSC machining centers. Its dynamic balance grade is G2.5 when the speed is 25000 RPM. - Tool change in seconds, micron-level precision, no peripheral equipment.

It saves installation time and does not incur additional investment and energy costs due to the purchase of peripheral equipment. - Deflection accuracy adjustable to 0 μm

Rotational errors of tool holder and tool can be compensated by using 4 lateral positioning screws - Excellent vibration damping

prevents microbursts, achieves optimal workpiece surfaces, protects machine spindles and extends tool life; all of which reduce costs - Precise axial length pre-adjustment

Length adjustment accuracy within 0.01 mm, adjustment stroke 10 mm - Wide compatibility

for perfect combination with TENDO SVL and TRIBOS SVL extensions. - Low-maintenance

fully enclosed system ensures long service life - All commercially available tool shank types can be clamped

Type A: with smooth cylindrical shank, Type A shank according to DIN 1835 and DIN 6535 HA Type AB: with cylindrical shank with flat surface and drawn face, Type AB shank according to DIN 1835 and DIN 6535 HB Type B: with transverse pull surface, shank B according to DIN 1835 Type E: with inclined clamping surface, shank E according to DIN 1835 and DIN 6535 HE - Drainage grooves for reliable torque transmission

Dry clamping surfaces by displacing oil, grease or lubricant residues into dirt grooves

Related Products

Related Cases

Welcome your message consultation