Short overhang long handle

TENDO ES with its zero-interference contour can be used when the available space within the machine tool is limited, even when calculations must be made with centimeter accuracy. SCHUNK extremely short hydraulic toolholders are ideal for machining large workpieces – even in tight spaces within the machine tool – and for drilling deep holes.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

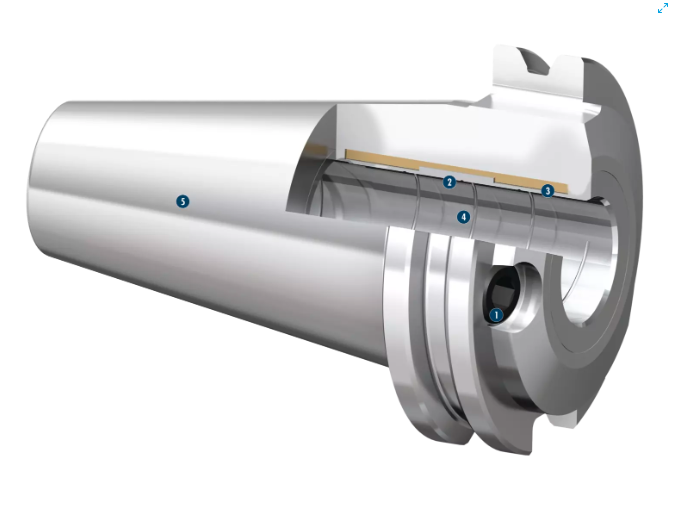

TENDO ES short overhang long handle

TENDO ES with its zero-interference contour can be used when the available space within the machine tool is limited, even when calculations must be made with centimeter accuracy. SCHUNK extremely short hydraulic toolholders are ideal for machining large workpieces – even in tight spaces within the machine tool – and for drilling deep holes.

The tool or extension is mounted directly into the interface cone. The interface cone is supported in the spindle. The result: maximum radial stiffness at high torques and lots of extra space in the machine tool.

1 clamping screw

pressurizes the bolt to move the drive piston. Use an Allen wrench to tighten the pressure bolt until it stops. No need to use a torque wrench.

2.

The expansion wall of the expansion sleeve expands evenly to press the tool handle. This clamping process first centers the tool shank before clamping completely over the entire surface.

3-Oil Chamber System

The chamber system filled with hydraulic oil has a vibration-damping effect on the clamped tool.

The huge clamping pressure of the 4-ring groove

TENDO hydraulic toolholder can squeeze oil, grease or lubricant residues into the ring grooves, keeping the surface dry.

5. The base

machine tool interface is located on the tool holder base.

advantage

- Interference-free contours

allow optimal freedom of movement in limited working areas - Standard precision dynamic balancing

is suitable for high speed conditions, and its balance level is G2.5 at a rotation speed of 25,000 RPM. - Tool change in seconds, micron-level precision, no peripheral equipment.

It saves installation time and does not incur additional investment and energy costs due to the purchase of peripheral equipment. - Continuous rotation and repeatability < 0.003 mm

Uniform cutting action, extended tool life and reduced costs for regrinding or purchasing new tools - Excellent vibration damping

prevents microbursts, achieves optimal workpiece surfaces, protects machine spindles and extends tool life; all of which reduce costs - Precise axial length pre-adjustment

Length adjustment accuracy within 0.01 mm, adjustment stroke 10 mm - High flexibility

thanks to grooved or coolant-proof reducing sleeves for clamping different diameters - Wide compatibility

for perfect combination with TENDO SVL and TRIBOS SVL extensions. - Drainage grooves for reliable torque transmission

Dry clamping surfaces by displacing oil, grease or lubricant residues into dirt grooves - All commercially available tool shank types can be clamped

Type A: with smooth cylindrical shank, Type A shank according to DIN 1835 and DIN 6535 HA Type AB: with cylindrical shank with flat surface and drawn face, Type AB shank according to DIN 1835 and DIN 6535 HB Type B: with transverse pull surface, shank B according to DIN 1835 Type E: with inclined clamping surface, shank E according to DIN 1835 and DIN 6535 HE

Options and special information

- Reducing sleeve for more flexible clamping range

Using one tool holder, the reducing sleeve can be used to clamp tools with a diameter of 3 - 32 mm. Your advantages: lower acquisition costs and greater clamping force on the tool shank.

Related Products

Related Cases

Welcome your message consultation