Rail milling cutter

The necessity of rail milling: > Able to meet the railway smoothness requirement ≤0.2mm/m > Able to improve the shortcomings of low transmission grinding operation efficiency and environmental pollution, especially suitable for implementation in the closed environment of the subway. > Rail milling operation has high repair efficiency and no pollution.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

1. Development Background

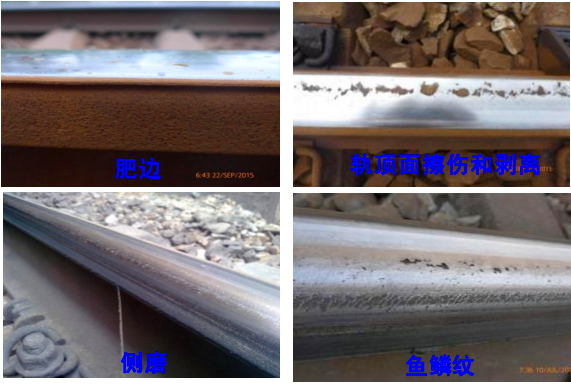

The Speed History of China's High-Speed Rail: 200→ 250→ 300→ 380 km /h; In order to ensure to ensure the safe operation of high-speed rail , the requirement for the rail unevenness per meter must not exceed 0.2 mm ; Under high-speed and heavy-load long-term operation, railways will experience Under high speed, fat edges, rail top surface scuffing or peeling, side wear, fish scale patterns, and other defects.

Rail defects change the normal wheel-rail relationship , seriously affecting train vehicle operational stability, passenger comfort, and driving safety.

By the end of the end of 2022 , the national railway operating mileage reached 155,000 kilometers , including high-speed rail over 42,000 kilometers, with 4,100 kilometers of new lines put into operation, including 2,082 kilometers of high-speed rail. There is a strong need for railway rail defect removal and maintenance.

The necessity of rail milling

> can meet the railway smoothness requirements ≤0.2mm/m

> can improve the shortcomings of low transmission grinding operation efficiency and environmental pollution disadvantages , especially suitable for implementation in the closed environment of subways

> Rail milling operation has high repair efficiency , no pollution

Subway Rail Milling Vehicle

2. Product Introduction

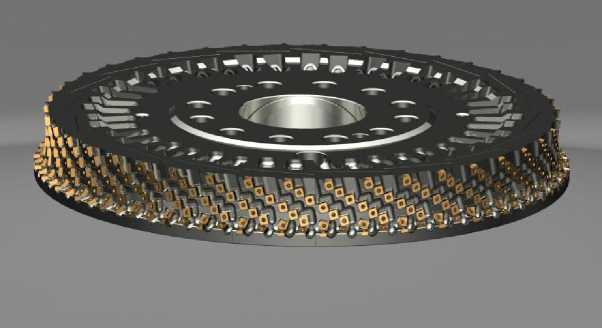

Application

Profile accuracy: ±0.2mm

Radial runout: ±0.02mm

Cutter diameter : 1100mm

Cutting parameters:

1. Maximum cutting depth: 0.3-0.5mm

2. Linear velocity: 120-180m/min

3. Feed rate: 1.8km/H

Advantages

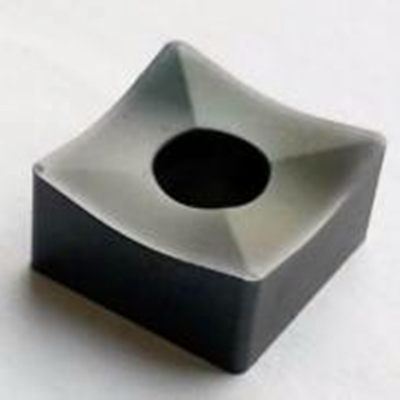

1. High-quality special steel, special surface treatment, makes the cutter head can work stably for a long time.

2. Optimized design, uniform control of the cutting force of each set of blades , Increase blade life.

3. Excellent processing technology and reliable processing equipment, Blade runout control 0.02mm within, high surface quality No secondary processing is required.

4. Higher processing efficiency, in a limited construction window Longer processing distance.

5. Small environmental impact, will not cause iron filings and dust pollution Long tunnel processing without downtime.

Related Products

Related Cases

Welcome your message consultation