Rail milling inserts

> Optimal design of tool geometry parameters > G level (±0.025) blade precision control > Ultra-fine grained tungsten carbide particles strengthen and toughen the matrix > Advanced PVD nano-composite coating technology > Special coating post-treatment process ensures the stress state of the coating

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

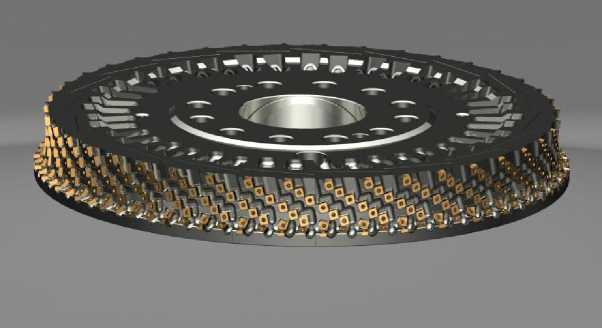

Product Description

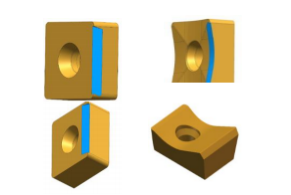

Rail milling inserts

Excellent performance guaranteed:

> Optimal design of tool geometry parameters

> G level (±0.025) blade precision control

> Ultra-fine grained tungsten carbide particles strengthen and toughen the matrix

> Advanced PVD nano-composite coating technology

> Special coating post-treatment process ensures the stress state of the coating

Practical processing applications:

Comparison before and after milling of diseased rails

Model and specification introduction:

The product has the following features:

1. High chemical stability, red hardness, wear resistance, thermal shock resistance and coating crack resistance, with a service life of up to 1.5 Km /edge;

2. At a traveling speed of 1.5~2.5 km /h and a relative milling speed of 170 ~240m/ min , the applicable milling depth can reach 0.5~0.8 mm , and the repair effect can be achieved in one pass;

3. The blade has strong adaptability to different diseases such as fat edges of the rails, peeling off of the tread, fish scales on the surface, and corrugation.

3. The blade has strong adaptability to different diseases such as fat edges of the rails, peeling off of the tread, fish scales on the surface, and corrugation.

Related Products

Related Cases

Welcome your message consultation