Non-falling wheel lathe heavy turning blade

The non-falling wheel lathe is mainly used to measure and repair the wheel rims and treads of subway vehicle wheelsets under the condition that the subway vehicles are assembled without disintegration. It is also suitable for the machining of a single bogie and a single wheel pair with an axle box. Repair and processing. It can complete the wheel turning processing of engineering vehicles such as shunting machines and flatbed trucks to keep the wheelsets in good condition.

Key words:

Classification:

Key words:

Tool matrix-Fixture matrix

Product Description

The non-falling wheel lathe is mainly used to measure and repair the wheel rims and treads of subway vehicle wheelsets under the condition that the subway vehicles are assembled without disintegration. It is also suitable for the machining of a single bogie and a single wheel pair with an axle box. Repair and processing. It can complete the wheel turning processing of engineering vehicles such as shunting machines and flatbed trucks to keep the wheelsets in good condition.

Non-falling lathe machine workshop

There are two main ways to process vehicle wheel sets without wheel drop: turning and milling.

1. The turning tool is a turning tool. Generally, there are two blades on the cutter head (but only one blade is in working condition). One blade cuts the tread surface and the adjacent rim surface, and the other blade cuts the other side of the rim. The wheel rotates rapidly under the drive of the driving wheel, and the blade moves according to the shape of the wheel rim tread - it can be cut directly according to the plate shape or according to the computer program.

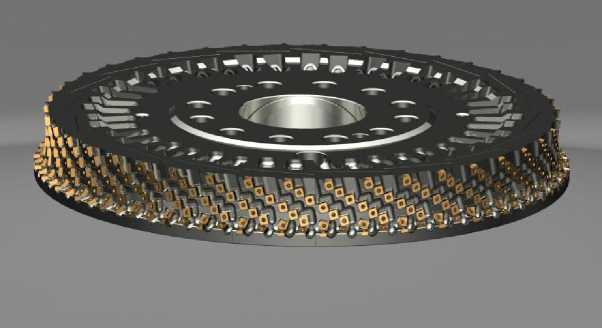

2. The milling tool is a milling cutter. Each set of full-contour copying milling cutters has multiple carbide inserts embedded in a surrounding and staggered manner. They contact the entire rim tread in sequence during milling. There are 10 to 16 cutting blades on the milling cutter wheel. Each blade is embedded with about 12 carbide inserts. The non-linear cutting length can maintain a low load and high cutting volume cutting state.

The primary considerations for railway wheel heavy vehicles are:

When heavy turning, it is best to choose the largest possible depth of cut to achieve a short processing time. However, this depends heavily on the wear condition of the main components of the wear wheel.

When heavy rolling train wheels, always use dry machining. Therefore, the requirements for the tools will be very high. When selecting tools and inserts, the following matters should be considered:

1. The type of wheel to be re-turned

2. The wear condition of the main parts of the wearing wheel

3. The available machine power

4. In some cases The contour can be turned in one pass.

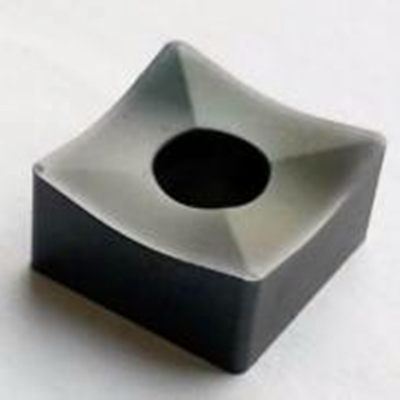

Commonly used blade specifications for non-turning lathes:

LNUX 19 19 40

LNUX 19 19 40

LNUX 30 19 40

LNUX 32 12 48

CNMX 19 11 40

LNMX 50 14 32

LNUX 32 12 48

Related Products

Related Cases

Welcome your message consultation